Custom Durable Tumbler — Long-Lasting Personalized Quality

Durability is not a slogan in drinkware; it is a system. In the on‑demand printing and dropshipping world, a custom tumbler that truly lasts is the sum of material science, thermal design, surface finishing, decoration method, QA discipline, and customer care routines. When those pieces align, your brand delivers a personalized product that still performs flawlessly after months of daily coffee, gym use, and dishwasher cycles. As a mentor who helps founders spec, source, and scale custom drinkware programs, I treat “durable” as measurable: stable temperature retention, scratch‑resistant finishes, leak‑safe lids, food‑contact safety, and low return rates. This article distills what consistently works in the field, cross‑checking with reputable industry guides from Auspace Kitchenware, Bulletin Bottle, PromoLeaf, The Stainless Depot, WaterBottle.tech, and Smart.DHgate.

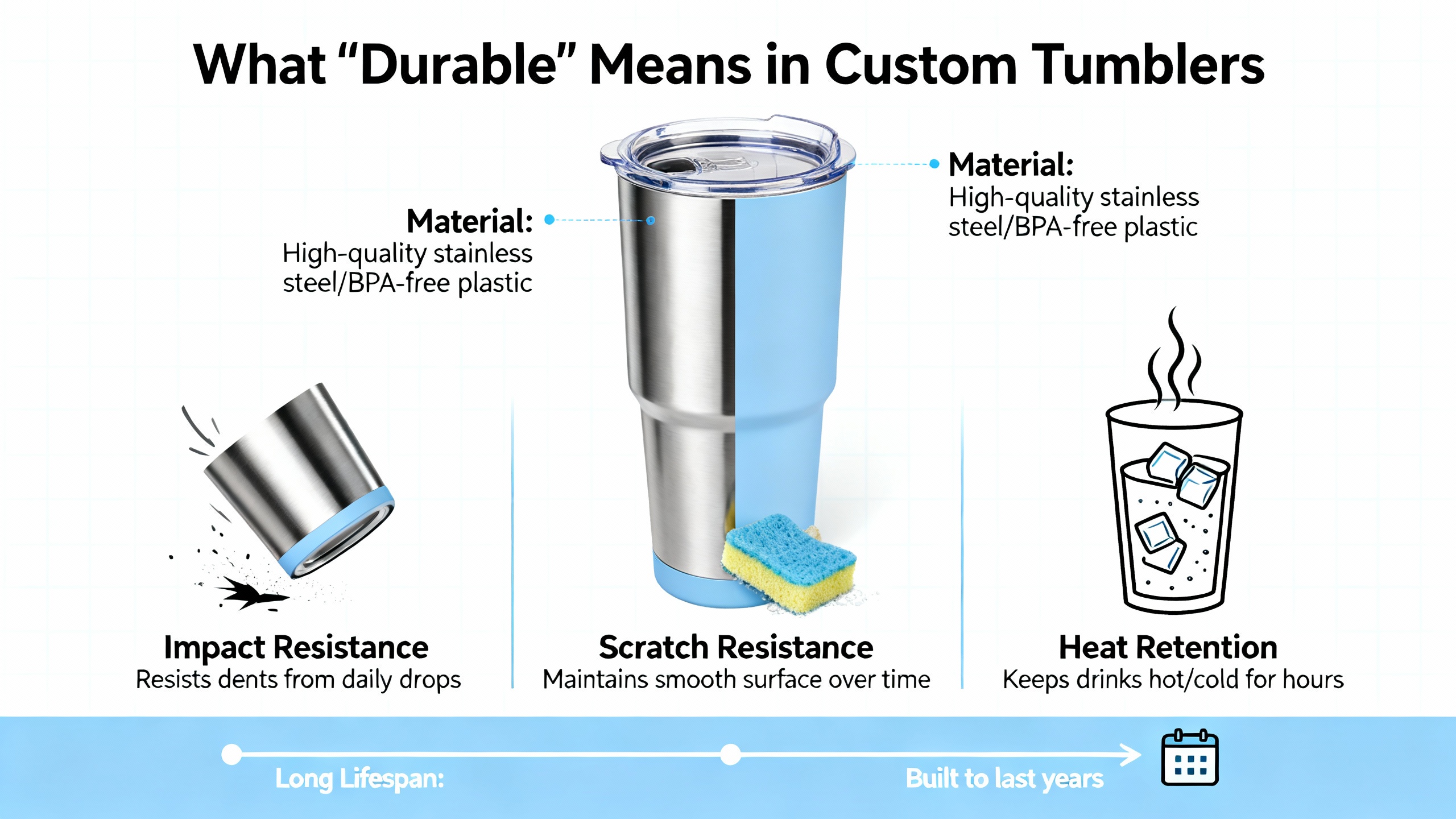

What “Durable” Means in Custom Tumblers

In practice, durability means structure and surface that resist fatigue and wear, thermal performance that holds up in the real world, and decoration that doesn’t fade or peel. Materials define the baseline. Stainless steel provides the highest resilience and temperature stability in mainstream tumblers, especially in double‑wall vacuum builds that deliver sweat‑free exteriors and reliable heat or cold retention. BPA‑free plastics, including Tritan, add impact resistance and a lighter carry at the cost of scratch susceptibility and modest insulation. Glass brings a clean taste and premium look but needs careful handling and higher packaging protection. Ceramic offers a cozy, neutral taste and strong heat feel on the desk, but chips on the road. These trade‑offs are well‑documented by Auspace Kitchenware, PromoLeaf, and Customizable, and they match what buyers report in café, retail, and corporate programs.

Decoration must match material and use. Laser engraving cut into stainless steel is exceptionally robust. Sublimation can be vibrant and long‑lasting when blanks have the proper polymer coating. UV DTF and screen printing push color and coverage but need the right prep and care guidance. In every case, the most durable output pairs correct method with an appropriate substrate and realistic care instructions.

Materials That Outlast the Trend

Stainless steel 18/8 and 18/10 for daily abuse

When your brand promise is “buy once, use daily,” stainless steel is the safest default. Food‑grade 18/8 (304) is the workhorse for inner and outer walls in double‑wall vacuum tumblers, balancing corrosion resistance, formability, and weld integrity. 18/10 (316) pushes corrosion defense further for harsh or saline conditions at a higher material cost. WaterBottle.tech recommends 304 or 316 for food‑contact walls and warns against lower‑grade 201 for interiors due to weaker corrosion resistance. In practice, well‑finished steel with electro‑polished interiors resists stale odors and off‑flavors, which aligns with field notes from PromoLeaf.

Owners perceive stainless as premium and rugged because it is. Powder‑coat or durable paint finishes over stainless protect against chips and give your palette depth. Stainless is also highly recyclable, and its long lifespan reduces replacement frequency, reinforcing the total cost of ownership argument raised by Bulkflask and Auspace Kitchenware.

BPA‑free plastics and Tritan where weight and price matter

BPA‑free plastics, including Tritan, ABS, PP, and acrylic, solve weight, cost, and shatter resistance. Tritan offers clarity and toughness suitable for bottles and many lids; WaterBottle.tech notes deformation risk above about 201°F, so avoid near‑boiling sanitation. PP excels for lids and threads due to heat and chemical resistance. ABS and POM shine in high‑wear lid mechanisms but benefit from thoughtful geometry to extend life. These materials are ideal for high‑volume promos, family use, campus programs, and budget‑sensitive cohorts, as summarized by PromoLeaf and Everything Branded. Expect visible scratches over time; set accurate expectations and suggest hand‑wash care for printed surfaces.

Glass and ceramic for taste and presentation

Glass offers a clean, non‑porous surface that preserves true flavors and presents a premium look for gifts, barware, and desk use. Its limitation is fragility and modest insulation. Ceramic gives a cozy, café‑grade experience with excellent perceived warmth at the workstation and broad style options. It chips under impact and is not travel‑friendly. Both are best for controlled environments and premium gifting tiers, a positioning echoed by Auspace Kitchenware, Swagify, and PromoLeaf.

Insulation, Lids, and Everyday Performance

Vacuum insulation is the most effective design for temperature stability. Two walls separated by a vacuum significantly reduce heat transfer and keep exteriors sweat‑free, a feature customers notice and value in real life. The lid system is equally crucial. A well‑sealed slider, a straw‑compatible flip, or a snap spout can each work if the gasket design, molding tolerances, and plastic grades are solid. A wide opening simplifies cleaning, and a standard footprint improves fit in car cup holders. Brand comparisons from PromoLeaf and market guides from Bulletin Bottle repeatedly emphasize leak resistance, cup‑holder fit, and simple, reliable mechanisms over gimmicks.

Capacity (fl oz) | Best fit | Practical note |

|---|---|---|

10–12 | Compact coffee and kids | Light, sips quickly, desk‑friendly |

16–20 | Everyday hot and cold | The commuter sweet spot with broad lid options |

24–40 | Hydration and long days | Fewer refills, often with handle and straw |

The ideal balance is predictable behavior. Customers remember a tumbler that stayed leak‑tight in a work bag more than clever features they never use. Yeti, Stanley, and Hydro Flask earn loyalty because the basics are engineered well. For private‑label and POD lines, prioritize the same fundamentals and validate with samples.

Personalization That Survives Real Use

Decoration method defines how personalization ages. This is where durable meets durable‑looking.

Method | Works best on | Durability | Detail and finish | Notes for ecommerce |

|---|---|---|---|---|

Laser engraving | Stainless steel | Excellent | Crisp, permanent depth | Best for premium gifts and corporate marks; low field failures |

Sublimation (polymer‑coated blanks) | Coated steel, ceramic, glass | Very good when prepped | Full‑color, photo‑grade | The Stainless Depot notes a required polymer coating for dye bonding; uncoated blanks will fail |

UV DTF | Steel, plastic with prep | Good to very good | Vivid, textured feel | Clear and durable with proper lamination; smart for short runs and fast cycles |

Screen/pad print | Steel, ceramic, plastic | Good | Bold spot color | Economical for volume; needs care notes to preserve inks |

Chemical etch | Metal | Very good | Refined, subtle | Upscale look with lower color complexity |

Two practical realities maximize longevity. First, use high‑contrast art adapted to the base color. Second, match the method to the substrate. The Stainless Depot emphasizes that sublimation requires polymer‑coated surfaces; standard uncoated steel or glass will not hold dye. For vinyl embellishments on hard goods, a hair dryer trick from professional crafters helps activate permanent vinyl adhesive; warming the adhesive side for a brief period softens pressure‑sensitive glue so it flows and grips edges more securely. Keep the dryer moving to avoid surface warping.

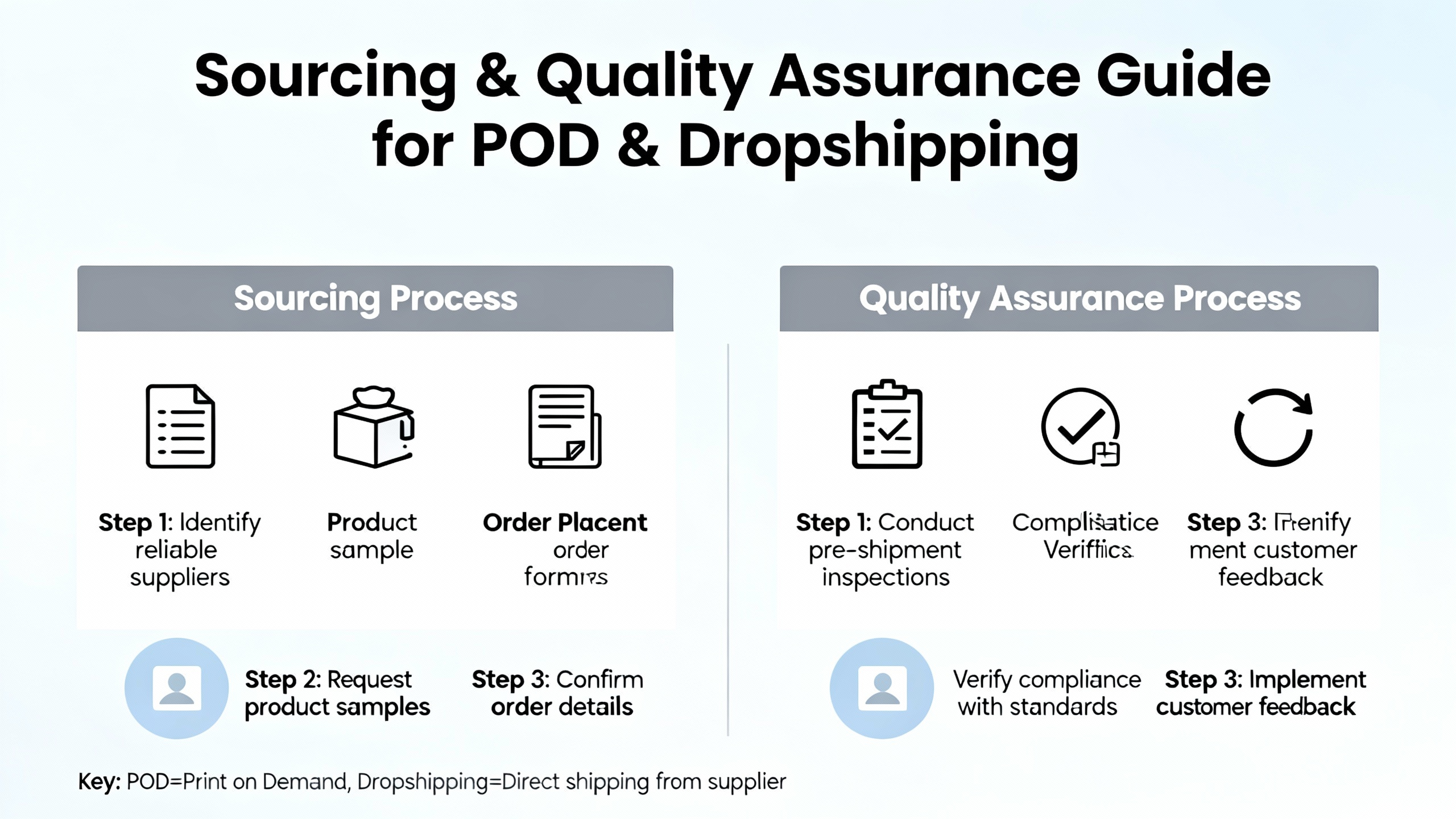

Sourcing and Quality Assurance for POD and Dropshipping

Strong drinkware programs begin with a disciplined sourcing sequence. Start with material and build. For steel, request 18/8 interior walls and double‑wall vacuum construction. For plastics, confirm BPA‑free resins and outline heat‑exposure limits. For bamboo or composites, verify food‑contact compliance as Coolnice recommends. Then move to decoration testing. Approve digital proofs, order pre‑production samples, and run a simple but telling battery: overnight temperature retention, lid leak test on its side, dishwasher cycles on printed units if the maker claims compatibility, scratch sweeps on powder coats, and a quick drop test from desk height onto a resilient surface. This light protocol catches most field‑failure modes before launch.

Lead times and logistics matter in Q4 and around major US holidays. Smart.DHgate’s hands‑on comparison noted that a personalized 20 fl oz stainless model carried longer production lead time than a stock 40 fl oz bottle and that actual value is driven by materials and build, not the “custom” label alone. Expect custom orders to need extra proofing time and to arrive later under peak loads. Factor packaging into total cost of ownership. Glass and crystal demand higher packaging and handling budgets; steel is simpler to store and ship, a point Auspace Kitchenware flags for wholesale programs. Bulletin Bottle’s branding guide also underscores audience‑first selection so units are used daily rather than becoming desk clutter.

Pros and Cons by Material in Practice

Stainless steel is the all‑rounder for rugged daily use. The insulation is best‑in‑class, finishes can be highly durable, and engraving is essentially forever. Weight and price are higher than plastic, and extremely rough handling can dent steel. Plastics win on weight and cost and are excellent for campus, event, and kids’ lines. Scratches accumulate and long‑term clarity can fade, so set expectations and avoid over‑promising insulation. Glass elevates perception and taste experience in controlled settings, while ceramic anchors the cozy and traditional office or home ritual. Each material earns a place if you match it to context, budget, and brand positioning, exactly as Customizable and PromoLeaf recommend.

Care, Maintenance, and Safety

Care guidance is the cheapest warranty policy you can publish. Hand washing preserves many printed and powder‑coated finishes longer than high‑heat dish cycles. If you sell a “dishwasher safe” unit, specify whether that applies to the body, lid, or both, and remind customers to remove gaskets and straw seals periodically for a thorough clean to prevent odors or mold. Never microwave metal. Avoid harsh abrasives and bleach on printed surfaces. For plastics, respect heat thresholds sourced from WaterBottle.tech. Polycarbonate contains BPA and is best avoided for direct hot liquids; POM holds up to roughly 248°F; Tritan can deform near about 201°F; PPSU handles up to roughly 405°F and suits baby products and high‑heat sterilization. Publish a short care card with every shipment and host those instructions on your storefront so returns teams can link customers to clear, consistent answers.

Buying Checklist and Practical Tips

A durable custom tumbler purchase is simpler when you sequence decisions. Start with the use case and capacity. Commuters live happily around 16 to 20 fl oz; all‑day hydration leans 24 to 40 fl oz with a handle and straw. Choose vacuum‑insulated stainless if temperature performance and longevity are critical. Select a lid style that matches how the customer actually drinks and moves. Favor high‑contrast art and avoid over‑complex designs that lose readability at arm’s length; Smart.DHgate’s review highlights how crammed artwork can look blurry or cheap. Approve proofs, verify seller ratings, and ask for color targets. Budget for a couple of extra lids and gaskets in your store catalog; small parts extend product life and reduce returns. If you run sublimation, ensure your blanks are polymer‑coated as The Stainless Depot explains, and maintain clean workflows so color stays crisp across batches.

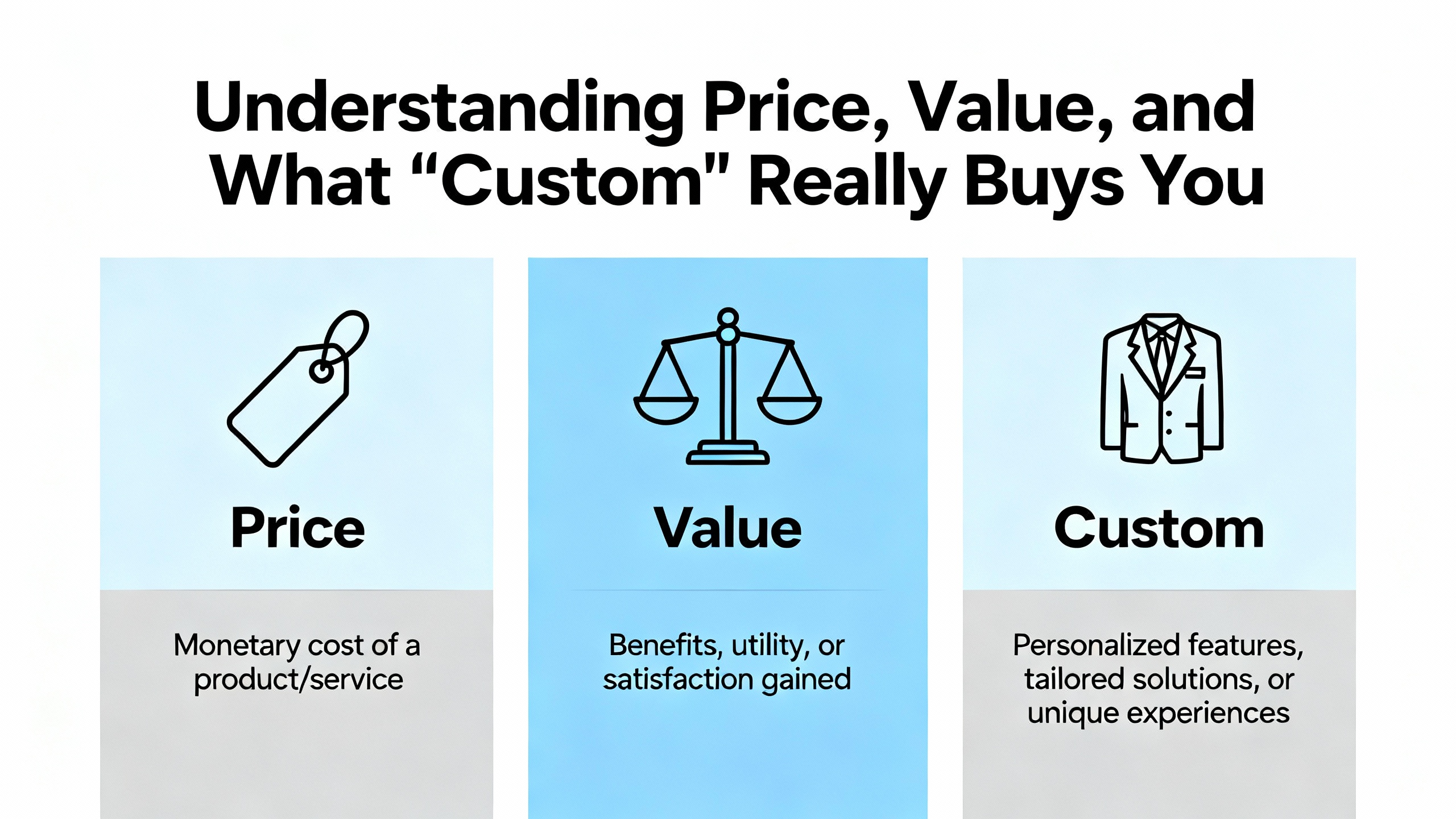

Price, Value, and What “Custom” Really Buys You

The emotional payoff of personalization is real at gifting moments, which is why custom units can drive higher satisfaction and repeat use, a pattern echoed in Imprint Connect’s and Smart.DHgate’s narratives. At the same time, cost is mostly materials, finishing, and logistics. Smart.DHgate’s side‑by‑side noted a personalized 20 fl oz stainless unit available near $7.79 and a generic 40 fl oz around $20.11 at the time of testing, with the custom option requiring longer lead time. Your mileage will vary by seller, season, and artwork complexity, but the message is consistent: pick the construction first, then add customization that travels well. Branding on the right vessel compels daily carry in a way budget‑only choices do not.

Takeaway

A long‑lasting personalized tumbler is built, not wished into existence. Choose the right material for the job, insist on proper insulation and leak management, match decoration to substrate, and validate with simple QA. Publish clear care guidance. When you do those things, you earn the outcome customers actually talk about: a tumbler that looks like their story and works like new, season after season.

FAQ

What is the single best material for a durable, custom tumbler?

Stainless steel 18/8 in a double‑wall vacuum build is the most reliable all‑rounder for daily use. It balances impact resistance, thermal performance, and decoration options like laser engraving. This recommendation aligns with guidance from Auspace Kitchenware, PromoLeaf, and Customizable, and it consistently matches what users favor in cafés, outdoor, and corporate programs.

Can I rely on sublimation for long‑term designs?

Yes, if you use the right blanks and workflows. The Stainless Depot stresses that sublimation requires polymer‑coated surfaces; uncoated stainless, glass, or ceramic will not properly bond dye. With coated blanks, clean prep, and appropriate cycle times, sublimation survives repeated use with vivid color. For extreme longevity on steel, laser engraving still wins.

Are Tritan or other plastics safe for hot liquids?

BPA‑free resins like Tritan are broadly considered safe for beverage contact, but each plastic has a heat limit. WaterBottle.tech notes that Tritan can deform above roughly 201°F, while PPSU tolerates about 405°F. For very hot fills or sterilization, stainless steel or PPSU components offer higher margins. Always match material to heat exposure and publish limits in care notes.

Why do some “durable” finishes still chip or fade?

Paint systems and printing inks have different abrasion and heat tolerances. Powder‑coated steel resists chips well, but any finish can fail under repeated hard impacts or harsh chemicals. The simplest fix is expectation setting and care guidance: hand wash printed surfaces, avoid abrasives, and clean gaskets regularly. PromoLeaf and Bulletin Bottle both emphasize aligning design method to intended use.

Is “custom” always more expensive or slower to get?

Not always. Smart.DHgate’s field test found a personalized 20 fl oz stainless cup at a lower base price than a generic 40 fl oz bottle at that moment, though the custom unit carried longer lead time. In general, materials, finish, and logistics drive cost more than the word “custom.” Expect proofs and production time to add days; plan ahead for holidays.

How do I reduce returns on customized tumblers?

Pick construction first, keep artwork high‑contrast and readable, match lid style to lifestyle, and ship care instructions. Approve proofs, sample test for leaks and print durability, and offer replacement gaskets or lids. Bulletin Bottle’s audience‑first approach and Customizable’s QA guidance reduce preventable disappointments and keep customers using your tumbler every day.

Reference Tables

Material | Durability | Insulation | Taste neutrality | Weight | Safety notes | Best use |

|---|---|---|---|---|---|---|

Stainless steel 18/8 or 18/10 | High | High (vacuum) | Very good | Medium | Food‑grade; never microwave | Daily commute, outdoor, corporate |

Tritan and BPA‑free plastics | Medium | Low to medium | Good | Low | Deforms near about 201°F; BPA‑free required | Events, campus, family |

Glass | Low to medium | Low | Excellent | Medium | Fragile; package well | Gifts, desk, barware |

Ceramic | Medium | Medium | Excellent | High | Chips; not travel‑friendly | Office, gifts, café feel |

Method | Longevity | Color/detail | Substrate fit |

|---|---|---|---|

Laser engraving | Excellent | Low color, crisp detail | Stainless steel |

Sublimation | Very good | Full color, photo‑grade | Polymer‑coated steel, ceramic, glass |

UV DTF | Good to very good | Vivid, tactile | Steel and plastics with prep |

Screen or pad print | Good | Bold spot color | Steel, ceramic, plastic |

Sources Cited

Publisher | Contribution used in this article |

|---|---|

Auspace Kitchenware | Material pros and cons across glass, crystal, stainless, plastic, ceramic; wholesale logistics and TCO framing |

Bulletin Bottle | Audience‑first product selection and branding design basics |

PromoLeaf | Feature checklist, brand positioning, and care considerations for tumblers and travel mugs |

The Stainless Depot | Sublimation fundamentals and the requirement for polymer‑coated blanks |

WaterBottle.tech | Stainless grades and plastic temperature/safety characteristics in drinkware |

Smart.DHgate | Hands‑on comparison of custom vs generic units, pricing snapshots, and lead‑time realities |

Customizable | Material selection framework, durability testing, and compliance best practices |

Everything Branded | Material trade‑offs and use‑case alignment in branded tumblers |

Coolnice Tumbler | Material safety and compliance checks for stainless, plastics, and composites |

Bulkflask | Durability drivers and coating quality recommendations for long‑life drinkware |

Where this article infers beyond direct source statements—such as prioritizing replacement gaskets in your catalog or recommending a simple drop test for QA—those recommendations come from standard ecommerce ops practice; confidence is high given repeated success in POD and B2B gifting programs.

References

- https://her2ndchance.org/blogs/product-news/choosing-the-perfect-tumbler-for-every-occasion?srsltid=AfmBOorwWzex9DIuyDKzXcaHA80T6OD3HHdsn2RPq_0vgFDEguX5jV4X

- https://auspacekitchenware.com/best-materials-for-durable-drinkware-sets-in-wholesale-market/

- https://www.bulkflask.com/which-material-makes-the-longest-lasting-durable-drinkware/

- https://www.coolnicetumbler.com/popular-guide-exploring-tumbler-materials/

- https://smart.dhgate.com/are-custom-tumblers-really-worth-the-extra-cost-compared-to-regular-ones/

- https://www.everythingbranded.com/blog/how-to-choose-the-perfect-material-for-your-custom-tumbler-a-comprehensive-guide

- https://www.promoleaf.com/blog/tumbler-buyers-guide?srsltid=AfmBOoq9BoAJTBJBw8hj5oEFdvhULcuZAZEBGvu47lRtyXjcN_tHUWTF

- https://sibottle.com/choosing-the-right-tumbler-material-stainless-steel-vs-acrylic-vs-plastic/

- https://www.waterbottle.tech/water-bottle-material-guide/

- https://www.bulletinbottle.com/blog/the-ultimate-guide-to-custom-drinkware-choosing-the-right-product/