Quality Custom Print Products: Professional Printing Services

In fast-moving e-commerce and on-demand operations, quality print is not a luxury. It is a trust signal, a conversion lever, and a retention tool. As a mentor who has led brands through scale-up phases—from first trade show kits to nationwide dropship programs—I have seen quality print shorten sales cycles, reduce return rates, and lift average order values. What follows is a practical guide to professional printing services, built for founders and operators who need a straight path from concept to consistent output. It covers what “quality” actually means in this category, how to select the right method and materials, how to evaluate vendors, and how to care for products so they perform after delivery. When relevant, I cite publisher names whose content appears in the research, including Clockwork Print House via the Durham Short Run Shirts blog, GotPrint, NextDayFlyers, UPrinting, Printful, Smartpress, Walmart Business Print, Vistaprint, Velocity Print, AlphaGraphics, FedEx Office, and Quality Logo Products.

What “quality” really means in custom print

Quality is not a single trait; it is the sum of accuracy, consistency, durability, and fit-for-purpose. Accuracy means the piece matches the approved design in color, size, finish, and trim. Consistency means every unit in the run looks and behaves the same. Durability means the print withstands actual use, whether that is apparel that can handle repeated washing, a banner that resists weather, or a business card that still looks crisp after months in a wallet. Fit-for-purpose means you chose the right method, substrate, and finish for the end use. Industry best practices define quality indicators clearly: crisp lines, solid ink coverage, correct registration when multiple colors overlap, smooth gradients on digital prints, and a hand feel that matches the method and expectations. On garments, durability shows up in basic tests: stretch without cracking, minimal rub-off, and color-fastness after several wash-and-dry cycles. On signage, quality shows in opaque color on clear materials where intended, clean cut edges, and uniform gloss or matte.

The business case for quality printing remains strong. Velocity Print reports that direct mail commands meaningful attention, with open and read metrics that often exceed digital ad engagement. For founders, that attention is only valuable if the tactile experience and message clarity are high, which is exactly where quality print matters.

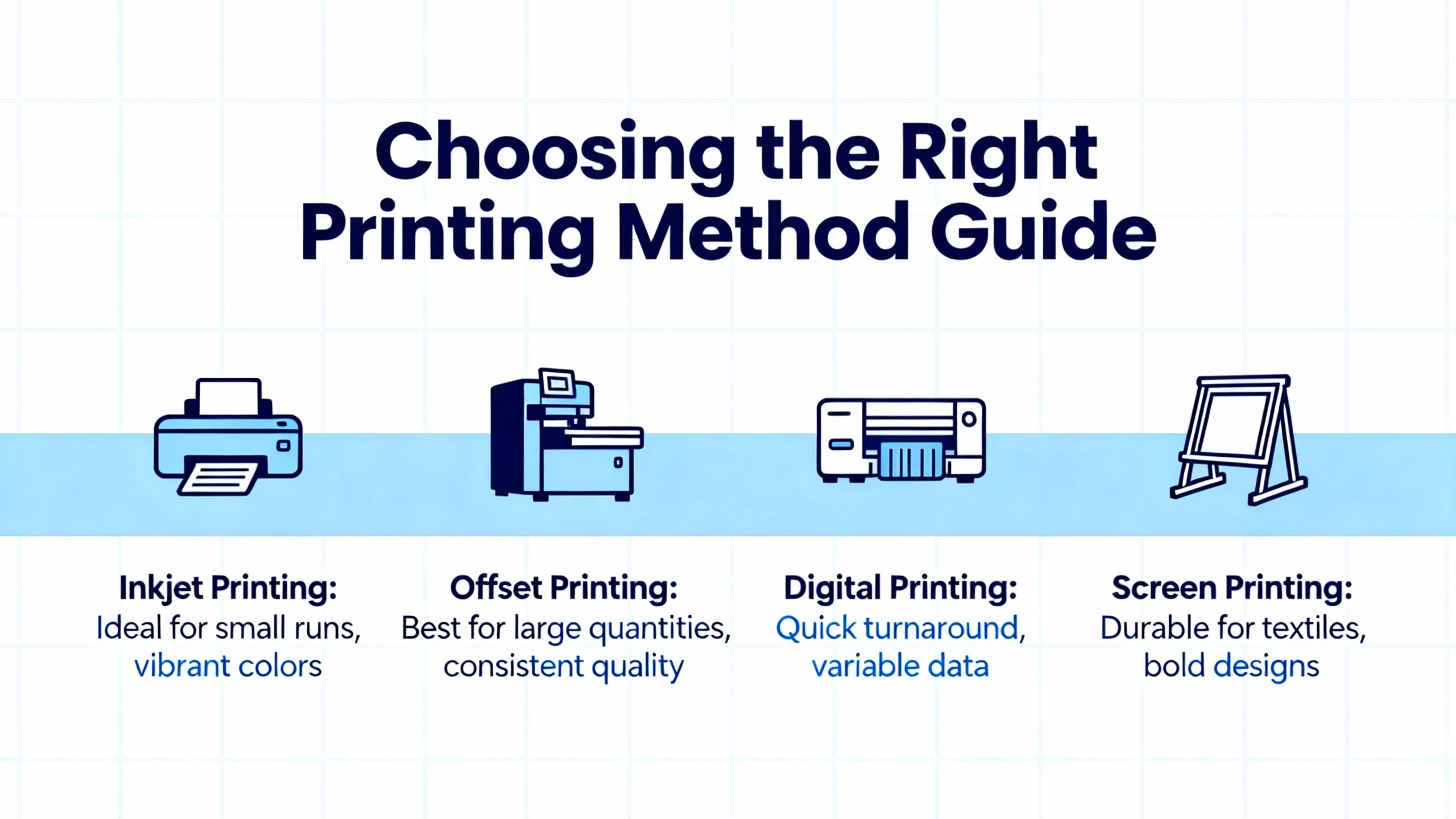

Choosing the right printing method

Method choice drives both results and unit economics. Screen printing pushes thick inks through mesh stencils for bold, opaque colors and long wear; it is a champion for large apparel runs and simple color counts. Heat transfer and direct-to-film (DTF) apply designs with heat and pressure, providing full color detail on varied fabrics with minimal setup, which is ideal for small to medium runs and personalization. Direct-to-garment (DTG) jets water-based inks directly into cotton-rich fabrics, producing soft, photorealistic prints but with less wash endurance than screen printing under heavy use. Sublimation fuses dye into polymer-coated surfaces and polyester fabrics for permanent, soft, unlimited-color prints; it is not for cotton or dark textiles. Inkjet for paper, stickers, and posters offers fast turnarounds and beautiful gradients for short runs. Eco-solvent wide-format printing excels at durable signage, vehicle wraps, and decals rather than apparel. Plastisol transfers are a screen-print variant that lets you press high-quality transfers on demand, useful for live events. Embroidery is not ink at all; it is thread-based decoration that delivers a premium, textured look for logos on polos, hats, and jackets, with exceptional longevity.

Clockwork Print House, via the Durham Short Run Shirts blog, recommends selecting by quantity, color complexity, material, durability needs, and turnaround. That matches real-world economics: screen printing is usually the lowest cost per unit at scale because setup costs are amortized across many pieces, while digital methods win for small runs and intricate art with gradients.

Quick comparison of printing methods

Method | Best uses | Core strengths | Key limitations | Order size sweet spot |

|---|---|---|---|---|

Screen printing | Bulk apparel, bold spot colors | Extremely durable, vibrant, opaque | Setup cost per color; gradients and micro-detail are harder | Medium to large |

Embroidery | Polos, hats, jackets, uniforms | Premium look, long-lasting, professional | Limited color blending; can distort thin/stretchy fabrics; cost rises with stitch count | Small to large, logo-centric |

Heat transfer (HTV) | Names, numbers, one-offs | Personalization, precise shapes, flexible film | Less durable than screen over many washes; manual process slows bulk | Single to small |

DTF (direct-to-film) | Full-color art on many fabrics | High vibrancy, broad fabric compatibility, no minimums | May be less durable than screen; slower for very large runs | Small to medium |

DTG (direct-to-garment) | Detailed art on cotton | Photorealistic prints, soft hand, no setup | Fades faster than screen under heavy washing; prefers high-cotton, light colors | Single to small |

Sublimation | Polyester apparel, mugs, decor | Permanent, soft, unlimited color | Not for cotton or dark fabrics; needs poly-coated surfaces | Single to medium |

Inkjet (paper/stickers) | Posters, labels, short-run collateral | High resolution, fast quotes and turn | Less durable on textiles; per-unit higher vs. screen at scale | Single to medium |

Eco-solvent signage | Banners, decals, wraps | Weather-resistant, long-lasting color | Not for apparel | Small to large |

Plastisol transfers | On-demand event pressing | Screen-print-like quality, flexible timing | Requires skill and extra steps | Small to medium |

Paper, fabrics, and substrates that elevate quality

Paper choice affects both look and durability. GotPrint highlights popular stocks such as 14 pt gloss, 16 pt matte, and 100 lb text, and even encourages requesting a free sample kit to feel differences before committing. For brand kits, heavier cards signal confidence while coated stocks enhance image vibrancy; uncoated stocks favor pen-friendly use cases like appointment cards and stationery. Fabric composition matters just as much. Ringspun and combed cotton improve detail and softness for DTG and screen printing, and cotton-rich blends accept ink predictably. Performance polyester demands different approaches, like sublimation for all-over graphics or DTF for flexible, vibrant spot placements.

On clear acrylic signage, Smartpress emphasizes the importance of spot white, which is a selectively printed white layer behind color to increase opacity and protect color fidelity where intended. They also note full bleed, which is printing edge to edge and then trimming so no unprinted border remains, and digital laser cutting, which allows unique silhouettes and cutouts with clean edges. For sustainability, Walmart Business Print points to Sustainable Forestry Initiative sourcing for certain paper products, which helps eco-conscious brands align packaging and print with stated values.

Sizing, finishes, and design readiness

Choosing standard sizes keeps costs predictable and speeds production. Business cards in the U.S. are commonly 2 x 3.5 in, which fits most cardholders and scanners. Postcards frequently run from 3 x 5 in up to 5 x 7 in for direct mail, while brochures are often 8.5 x 11 in in trifold for convenience and mailing. Booklets and catalogs commonly use 8.5 x 11 in for portrait layouts. For outdoor and directional signage, yard signs at 18 x 24 in and aluminum signs around 20 x 30 in are easy to spot from a distance without requiring oversized shipping. Stickers and roll labels at 2 in and similar small formats create budget-friendly brand touchpoints in every order. Folders can remain minimal—logo, contact, and slogan—and still feel premium with a soft-touch or matte laminate.

Before uploading artwork, confirm the basics. For raster images, 300 DPI at print size avoids pixelation on close inspection. For spot-color screen prints, vector artwork and Pantone guidance help vendors maintain color fidelity. DTG on dark garments benefits from a solid white underbase and correct pre-treatment; uneven pre-treatment appears as mottling after cure. Across paper products, plan for bleed and safe margins specific to each template, and review pre-production proofs carefully. NextDayFlyers underscores this with free design proofs for each order, and GotPrint further reduces risk by offering a first-time customer satisfaction guarantee on printing costs. That combination—proofs, sample kits, and guarantees—protects smaller teams from expensive learning curves.

Common print sizes at a glance

Product | Typical size | Practical note |

|---|---|---|

Business card | 2 x 3.5 in | Universal fit for wallets and scanners |

Postcard mailer | 3 x 5 to 5 x 7 in | Budget-friendly outreach and inserts |

Brochure (trifold) | 8.5 x 11 in | Easy to distribute and mail |

Booklet/catalog | 8.5 x 11 in | Flexible page counts for product ranges |

Yard sign | 18 x 24 in | Clear, high-visibility directions or ads |

Aluminum sign | Around 20 x 30 in | Weather-resistant storefront branding |

Sticker/label | Around 2 in | Low-cost brand touchpoints on shipments |

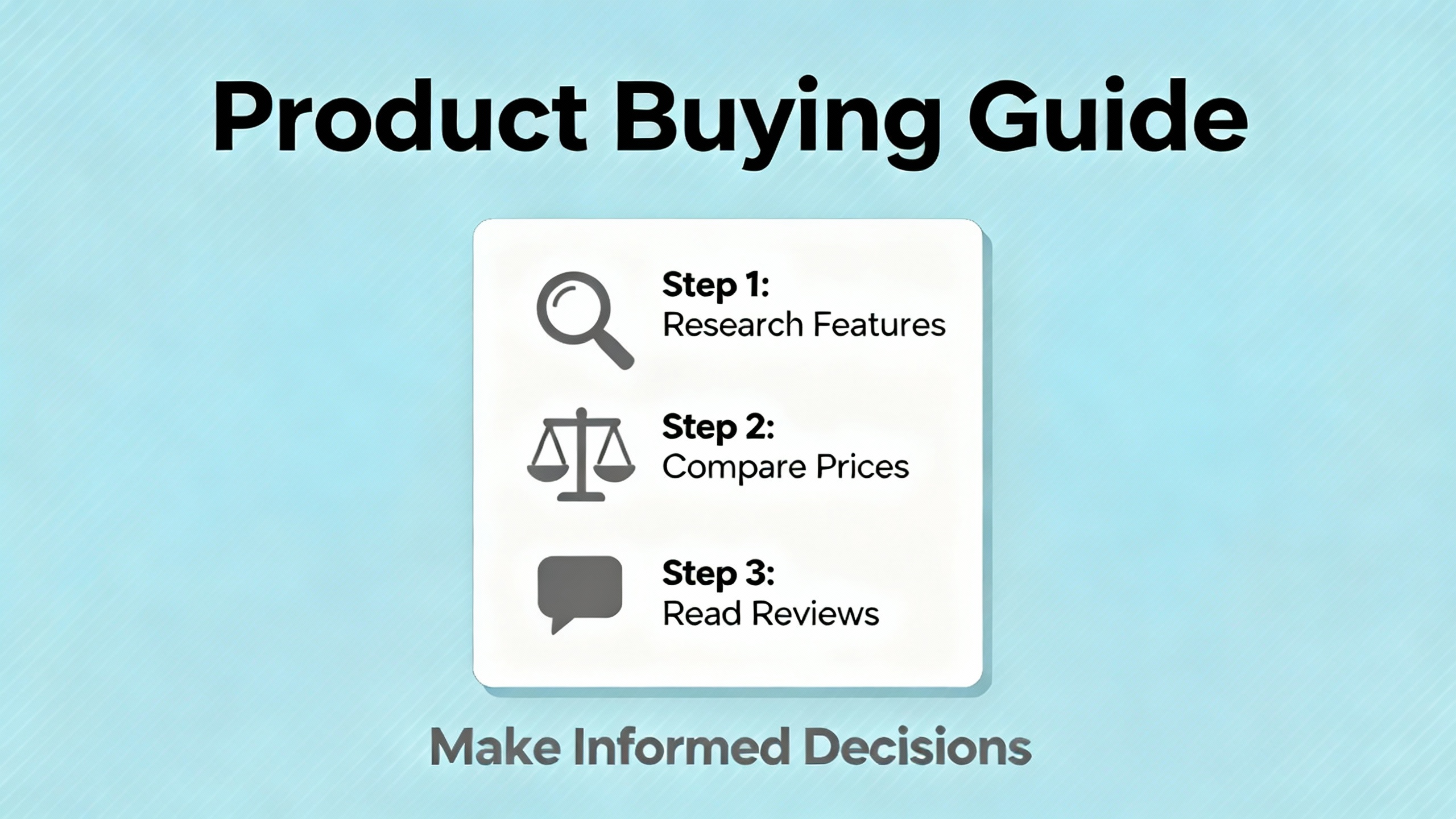

Workflow with professional printers

A crisp process protects your margin and calendar. Start by defining purpose, environment, and durability needs. For apparel, specify fabric type and expected wash cycles; for signage, note indoor or outdoor use, expected sun exposure, and installation surface. Share quantities by size or variant to unlock better pricing. Ask about proofs and checkpoints. Vendors such as NextDayFlyers claim a 99.8% on-time delivery rate and 33 quality checkpoints, while UPrinting cites a 33-checkpoint process and trust from more than 1,000,000 business professionals. Those signals help with vendor selection, but internal diligence is still essential: approve a single “golden sample” and keep it on file, so both sides share the same quality target.

Plan logistics early. 4imprint clarifies how packaging, fulfillment, and mailing services can be integrated into campaigns so your team focuses on messaging rather than kitting. For fast turn work, FedEx Office covers essential documents and marketing materials with accessible channels. When volume spikes or deadlines are tight, NextDayFlyers offers same-day and overnight production, while GotPrint and MOO highlight fast production and first-order promotions respectively. As a final safeguard, align shipping methods with promised delivery dates rather than relying solely on production speed.

Product-specific buying guidance

Business cards and stationery remain the brand’s handshake. AlphaGraphics describes them as foundational assets that support professionalism in daily operations. Cards stand out with soft-touch coatings, foil, embossing or debossing, and precision die-cuts; stationery suites unify letterhead, envelopes, and notecards for official and personal communications. Keep essential contact details present and legible.

Direct mail postcards are still underrated performance drivers. The GotPrint blog and Velocity Print both emphasize how physical mail earns attention, especially when paired with digital follow-up. For seasonal or local campaigns, pair postcard offers with yard signs and simple directional messaging. Postcards make useful package inserts as well—include a thank-you message and limited-time discount to encourage repeat orders.

Brochures and booklets do heavy lifting for complex offerings. An 8.5 x 11 in trifold is a versatile baseline, while catalogs and portfolios with 8 to 64+ pages showcase depth. Use clear sections to educate, address objections, and present options. For events, keep a few premium copies on heavier stock to share with high-intent prospects.

Stickers and roll labels give you the highest impressions per dollar across packaging and events. Keep branding consistent across shapes and sizes, and consider a simple 2 x 2 in logo-and-URL sticker added to every order. For product labels, confirm adhesion type and surface compatibility, then request samples to validate legibility at actual size.

Apparel and uniforms deserve a method-by-method approach. For durable large runs, screen printing on cotton or stable blends stays the reliable workhorse. For personalization, HTV and DTF enable names and numbers without expensive setups. For detailed full color on cotton-rich tees in small batches, DTG creates a soft feel and art-friendly gradients. For premium uniforms and hats, embroidery projects authority and lasts for the lifetime of the garment. Sublimation opens the door to all-over polyester prints and hard goods like mugs and decor.

Signs and displays should match viewing distance and conditions. Yard signs at 18 x 24 in are clear for drive-by or event use; aluminum plates deliver storefront longevity; eco-solvent banners and decals handle UV and weather. Smartpress calls out clear acrylic for modern, glass-like backdrops and award pieces, and recommends pairing backlighting with spot white to keep graphics readable and vivid.

Promotional products extend repeated touchpoints into daily life. Walmart Business Print and 4imprint describe common categories—drinkware, journals, magnets, calendars, towels, and desk items—that repeatedly reinforce brand presence without ongoing ad spend. Select practical items you know your audience will use, and leverage bulk pricing when preparing for large events.

Care and longevity: what to tell customers

Garments last longer when washed inside out in cold or warm water, then air-dried or tumble-dried low. Screen prints tolerate more heat and abrasion, while DTG and HTV appreciate gentler cycles to protect surface inks and films. For screen prints using plastisol inks, full cures around 320°F achieve maximum durability; incomplete cure manifests as cracking or premature wear. Recommend that customers avoid strong bleach and high-heat ironing directly over prints.

Paper pieces should be stored flat and dry, away from direct sunlight and high humidity. Coated stocks resist smudging but still benefit from clean handling. Adhesive labels adhere best to clean, oil-free surfaces; instruct buyers to wipe surfaces before application to avoid edge lift and bubbling. For clear acrylic, dust gently and avoid ammonia-based cleaners that can haze the surface.

Define a wash-test plan internally before launch. In practice, five to ten cycles reveal most print failures and dye migration issues on certain polyester reds. Approve a golden sample, document care instructions, and include those instructions on packing slips, product pages, or inserts so customers know how to protect their purchase.

Sustainability and material choices

Sustainable Forestry Initiative sourcing from providers like Walmart Business Print helps align paper usage with responsible forestry practices. The Printful blog notes sustainability differences across methods, with some digital processes presenting more eco-friendly traits than traditional solvent-heavy approaches. On apparel, water-based inks and efficient curing reduce environmental impact. On paper, recycled stocks and soy-based inks support ESG goals without sacrificing visual quality. At scale, even small per-piece improvements accumulate into meaningful footprint reductions.

POD and dropshipping playbook

If you are testing product-market fit or adding seasonal SKUs, a print-on-demand partner helps you avoid tying up cash in inventory. Printful’s guidance encourages founders to match method to fabric, design complexity, order volume, and sustainability goals, and to validate with small test runs. Vistaprint reminds teams to reuse core designs across multiple products to enforce brand consistency and lower design costs. For campaigns that require physical kitting and mailing, 4imprint’s packaging, fulfillment, and mailing support takes friction out of distribution. For on-demand paper and quick replenishment, FedEx Office and NextDayFlyers provide speed lanes backed by proofs and clear turnaround definitions. Mixam’s Smart Print Assistant is another example of how vendors are making choice architecture easier, guiding product selection, paper types, and finishes so non-experts can spec confidently.

Vendor signals and noteworthy offers

Source | Notable feature or claim |

|---|---|

NextDayFlyers | Same-day and overnight options, a claimed 99.8% on-time rate, and 33 quality checkpoints with free proofs |

UPrinting | A 33-checkpoint quality process and trust from more than 1,000,000 business professionals |

GotPrint | Fast production, a first-time printing-cost satisfaction guarantee, and free sample kits for stocks |

Walmart Business Print | Marketing materials produced to Sustainable Forestry Initiative standards for certain paper products |

Smartpress | Spot white on clear acrylic, full bleed guidance, and digital laser cutting for custom shapes |

Vistaprint | Encourages cross-product design reuse to maintain brand consistency and reduce design effort |

MOO | A first-order discount via their newsletter for qualifying orders, useful for initial tests |

Quality Logo Products | Social proof via high customer counts and ratings as a reliability signal |

Treat these as starting points rather than guarantees; always request current specifics, proofs, and SLAs before placing time-sensitive or high-value orders.

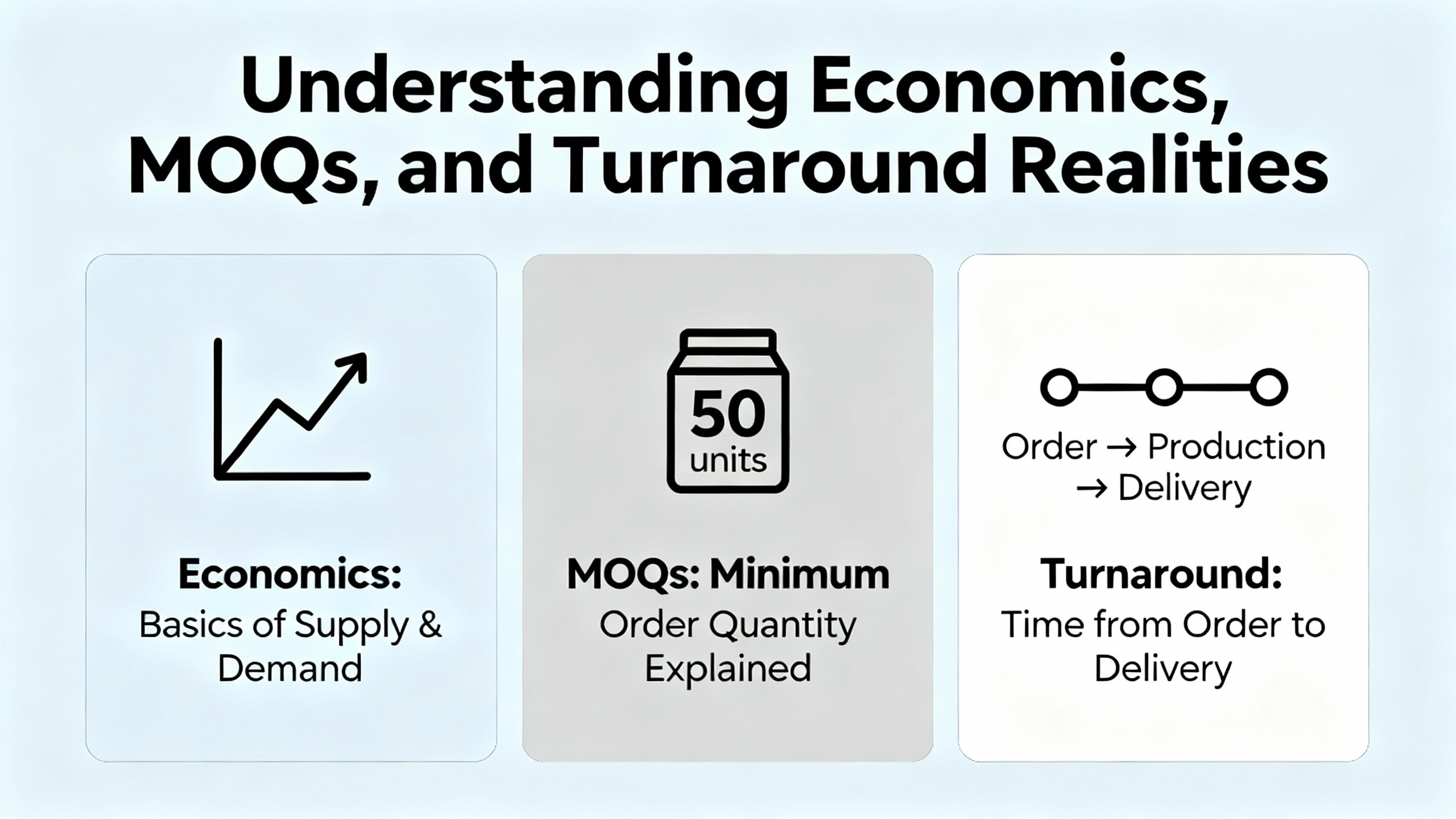

Economics, MOQs, and turnaround realities

Screen printing wins on unit economics at medium to large quantities because its setup cost is spread across more pieces. Digital methods such as DTG, DTF, and HTV shine at one-offs, personalization, and small batches where setup costs would otherwise dominate. Turnaround is a combination of production speed and shipping; the fastest production schedule paired with ground shipping may still miss your event. Some vendors, including NextDayFlyers, offer same-day or overnight production tied to cutoff times, while others, like GotPrint, emphasize overall fast production with multiple shipping options. Promotions can influence your cart strategy. Vistaprint’s tiered discounts reward hitting spend thresholds, and MOO’s first-order offer helps reduce risk on early prototype runs. For bulk promotional products or distributed kits, ask 4imprint to quote packaging and mailing so you can compare fully loaded costs across options.

Takeaway

Quality print is a strategic asset when it is designed for purpose, produced with the right method and materials, and delivered through a disciplined workflow. If you define success metrics up front, approve proofs and samples, and match each job to the method that fits its quantity and use, you will get consistent output that builds trust with customers. Use the vendor signals in this guide to shortlist providers, validate claims with proofs and tests, and then codify what works into your brand playbook. That is how founders convert print from a cost center into a durable advantage.

FAQ

How do I choose between screen printing, DTG, and DTF for T‑shirts?

Pick by art style, quantity, fabric, and durability needs. Screen printing is best for bold spot-color designs at medium to large volumes and excels in longevity. DTG is ideal for detailed, full-color art on cotton in small runs with a soft hand. DTF handles full color on varied fabrics with strong color and minimal setup, which is excellent for small to medium runs and personalization.

What proofing steps should I insist on before production?

Request a pre-production proof or sample and review color, trim, finish, and readability at actual size. For apparel, approve a golden sample printed on the exact garment and run several wash cycles. For paper, validate color on the chosen stock and confirm bleeds and margins. Vendors like NextDayFlyers provide free design proofs, and GotPrint offers first-time satisfaction protections on printing.

Which paper stocks are safe bets for business cards and brochures?

For business cards, 14 pt gloss or 16 pt matte from providers like GotPrint create a sturdy, professional feel; soft-touch laminates add a premium finish. For brochures, 100 lb text with a gloss or matte finish balances print clarity and foldability. If unsure, request a sample kit to compare stocks in hand before placing the order.

How can I keep printed apparel looking new after delivery?

Communicate care clearly. Turn garments inside out before washing, use gentle cycles with low to moderate temperatures, and avoid high-heat drying and ironing directly over prints. Properly cured screen prints tolerate more abuse; DTG and HTV benefit from gentler care. For plastisol inks, full cures around 320°F are a durability must.

Are acrylic signs practical for retail and events?

Clear acrylic delivers a sleek, glass-like look. Smartpress advises using spot white behind color to maintain opacity and legibility on clear substrates, and full bleed for edge-to-edge designs. Pair with backlighting for dramatic retail displays. Digital laser cutting allows unique shapes that can lift perceived value without inflating the footprint.

Is print still worth it in a digital-first strategy?

Yes, when it is integrated. Velocity Print highlights strong attention metrics for direct mail, and providers like Walmart Business Print, AlphaGraphics, and Vistaprint show how core materials—cards, brochures, labels, and posters—support both brand recall and operations. Use print to create tactile anchors that reinforce your online campaigns and give customers something to keep, share, or act on.

References

- https://www.smithprint.net/things-to-consider-when-choosing-a-printing-services-provider/

- https://www.4imprint.com/

- https://www.gotprint.com/home.html?srsltid=AfmBOoo4KLcpt-GGeEnGnd069gJYYr3elZajbprfP6_6A_28VYbkcVt9

- https://mixam.com/

- https://www.nextdayflyers.com/?srsltid=AfmBOoofzm5e3_OygKyvOpax2vR-CtFcHp1a7V7Njk4WxjlC1GHRxzRG

- https://www.qualitylogoproducts.com/

- https://theprintplug.com/choosing-the-best-custom-printing-techniques

- https://www.uprinting.com/?srsltid=AfmBOoo7vUVcEbMk9QorzyAtuD5JPBuWsjdsFanDBddP2Ji4FZmmmBgN

- https://www.vistaprint.com/?srsltid=AfmBOoo3ec2DN1rTW-LqByh_zMjWa1afjpwDNzF1UFrWy3ffy9UzHsY5

- https://durhamshortrunshirts.com/blog/how-to-choose-the-right-printing-method-for-your-project