Personalized Easy Grip Bottles — Comfortable Custom Handling

Introduction

Personalized easy grip bottles sit at the intersection of comfort, safety, and brand storytelling. When the bottle feels secure in the hand and the design reflects someone’s identity or a company’s message, carry rates go up and daily hydration becomes automatic. From a mentoring standpoint, I’ve watched teams, schools, and DTC brands increase usage and gifting uptake simply by prioritizing ergonomics alongside customization. This guide translates what independent reviewers, merchandising providers, and product engineers have learned about grip, lids, materials, and branding into practical moves you can use for an on-demand printing or dropshipping business.

What “Easy Grip” Really Means

In bottle design, “easy grip” is not a single feature—it’s a system. It involves a stable center of gravity, surface textures that resist slip, and forms that naturally guide fingers and palms. Industrial notes from bottle makers emphasize waist indentations, gentle hourglass or oblong contours, and textured finishes to support one-handed use, even with sweaty hands (ibottler). Shape decisions also affect stability, labeling, and manufacturability; for example, round bodies tend to distribute pressure evenly and run faster on automated lines, while square corners can concentrate stress and complicate labeling unless you plan for it early (Ajanta Bottle).

Independent product editors routinely reinforce the end-result of these engineering choices. Testers at The Strategist, CNN Underscored, GearLab, and Wirecutter consistently highlight how carry handles, tapered bases that fit cup holders, and well-designed mouthpieces make bottles easier and safer to use throughout the day. In other words, comfortable custom handling starts with sound ergonomics, then gets amplified by lid and handle decisions and finally by the personalization method that won’t compromise grip or durability.

Why Personalization Drives Adoption and Brand Value

Personalization transforms a commodity into a personal or branded asset. Retail and promotional providers note that engraving, wrap printing, and color-matched components can boost daily carry because the item represents identity or community. ProWorks and Swagify both frame personalization as an emotional hook that increases habit formation and long-term use, which in turn multiplies brand impressions over the life of the bottle. Major promo houses such as 4imprint and VistaPrint lower friction with art assistance, samples, low or flexible minimums, and multiple decoration methods. Photogift providers like Walmart Photo offer a range of vacuum-insulated stainless formats with central or full-wrap personalization panels that maintain a robust grip thanks to powder coats or matte textures.

From a merchandising perspective, the commercial case is straightforward: a bottle that is comfortable to hold and feels “mine” gets carried more often, which raises hydration adherence for the owner and keeps your brand in view. My professional experience aligns with this logic; while specific lift varies by audience and offer, the pattern is durable across school, fitness, and corporate use cases. This is a reason to treat grip and customization as first-order decisions, not afterthoughts.

Materials, Insulation, and Grip

Surface feel and weight matter as much as thermal performance. Stainless steel bottles with double-wall vacuum insulation tend to deliver the best temperature retention and a slightly grippy powder coat. BPA-free plastics reduce weight and cost and are often squeezable for sport use, which naturally supports one-handed grip. Glass maximizes taste purity but needs a sleeve for protection and grip; aluminum splits the difference on weight with modest insulation and a premium look.

Material | Grip and Feel | Temperature Control | Relative Weight | Personalization Fit | Typical Use Case |

|---|---|---|---|---|---|

Insulated stainless steel | Powder-coated textures add secure feel | Strong cold/hot retention | Heavier | Laser engraving or UV print | Daily carry, corporate gifts, premium kits |

BPA-free plastic | Light, squeezable, easy-grip contours | Limited; some insulated variants | Lightest | Screen/UV print; bulk-friendly | Sports teams, events, value giveaways |

Glass (with sleeve) | Sleeve adds grip and protection | None; relies on shade/environment | Heavy | UV print on sleeve or limited on glass | Office, taste-first users |

Aluminum | Light, smooth; add texture bands | Minimal without added insulation | Light | Laser or print; sleek appearance | Trade shows, travel-friendly |

Well-known brands reinforce these trade-offs in test results. GearLab and CNN Underscored highlight stainless steel for durability and impression of quality, plastic for lightness and drop resilience, and glass for taste. Nalgene’s “BPA Free” positioning is a category signal for safe plastics, and it’s widely recognized.

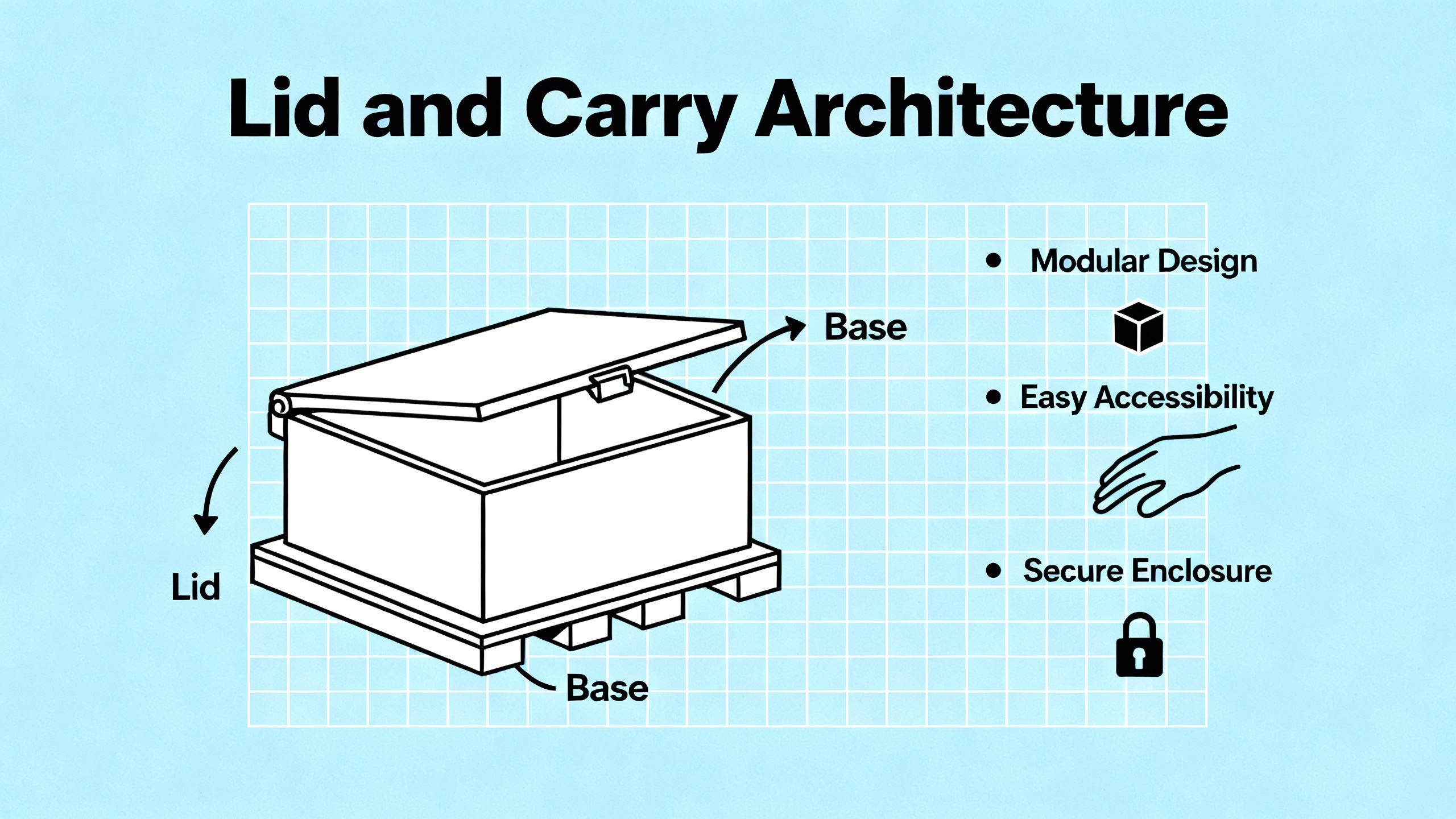

Lid and Carry Architecture

After the body, lids define the experience. Editors at CNN Underscored, The Strategist, Wirecutter, and BottlePro’s comparison work show how different closures impact one-handed use, leak control, cleaning, and perceived grip. Straw and chug designs increase flow rate and reduce the need to tilt. Flip-tops with locks protect the mouthpiece and prevent accidental openings in bags. Screw caps maximize sealing and easy scrubbing but often need two hands.

Lid Type | One-Handed Use | Leak Control | Cleaning Ease | Notes on Grip and Comfort |

|---|---|---|---|---|

Straw (covered) | Strong | Good when covered/locked | Moderate; straw requires brushing | Encourages frequent sipping; reduces wrist tilt |

Chug/Spout | Good | Good with cap or twist lock | Good; few crevices | Fast flow; secure hold while moving |

Flip-top | Good | Very good with latch/toggle | Moderate; hinges/springs to clean | Quick access; pocket-friendly |

Screw cap | Fair | Excellent | Excellent | Most durable seal; two-hand trade-off |

Push-pull nozzle | Strong | Good if gasket quality is high | Good | Classic sports feel; easy squeeze bottles |

Independent testing frequently notes that straw systems are easier to drink from while driving and can increase sip frequency during the day; The Strategist describes this behavior in long-term use. Wirecutter’s recent coverage of dual-mode straw-and-chug lids shows how design upgrades like physical locks, larger handles, and tapered bases support cup-holder compatibility and one-handed operation. For rugged use, CNN Underscored’s drop tests praise durable chug systems and ultrawide mouths that make cleaning and icing easier, which also supports sanitary grip.

Sizing for Comfort and Hydration

Bottle size influences both grip and compliance. A large bottle reduces refills but challenges one-handed control and cup-holder fit; a small bottle fits better in backpacks and kid hands but requires frequent refills. Practical ranges from group-buy and promotional playbooks suggest kids do well with around 12 oz and adults with 16–24 oz for day-to-day balance (Totally Promotional). Sports teams often standardize around approximately 28 oz for practice and games, which fits the sweet spot for fewer refills while staying portable. Design guidance from ibottler frames capacity bands by activity: about 8–12 oz for quick sessions or kids, about 17–20 oz for everyday use, and about 25–34 oz for endurance or long outdoor days.

A hydration reference commonly cited to groups is the Harvard Medical School note indicating roughly 2–3 cups of water per hour in typical conditions, which translates to 16–24 oz. A 16–24 oz bottle emptied hourly aligns with that pace, though individualized needs vary and medical advice should guide any specific regimen. In distribution programs, it’s practical to offer two sizes and a compatible lid family so users can tune comfort and intake without switching brands.

Capacity (oz) | Typical Fit | Handling and Grip Notes |

|---|---|---|

12 | Kids, short errands | Small diameter; easy for small hands; light |

16–24 | Everyday adult use | Best balance of grip, weight, and refills |

28–32 | Teams, training, long commutes | Fewer refills; requires carry loop or side handle |

40+ | All-day desks, outdoor base camps | Heavy; not cup-holder friendly; use with handle |

Personalization Methods and Durability

Not all decoration methods behave the same once the bottle is in hand and on the move. Laser engraving on stainless steel is the durability benchmark. UV/digital prints enable full color and photographic wraps with robust inks. Screen printing scales well in bulk for strong, high-contrast marks. Sublimation wraps on white-coated surfaces deliver 360° canvases with vibrant results. Providers such as 4imprint offer complimentary art assistance and samples to dial in sizing, curvature, and placement. Walmart Photo details multiple print zones and insulation configurations across sizes, which is helpful when balancing grip surfaces and design areas. VistaPrint’s catalog breadth and flexible minimums let you test multiple formats without overcommitting inventory.

Method | Durability in Hand Use | Visual Outcome | Speed/MOQ Considerations | Best For |

|---|---|---|---|---|

Laser engraving | Excellent; mark does not peel | Metallic reveal on steel | Fast; low minimums | Premium gifts, daily carry steel |

UV/digital print | Very good; resilient inks | Full color, gradients | Fast; low to moderate minimums | Teams, retail designs, photos |

Screen print | Good; bold spot colors | High contrast, simple art | Efficient in bulk | Events, value lines |

Sublimation wrap | Good; 360° vibrant coverage | Edge-to-edge imagery | Requires coated white surfaces | Artistic wraps, influencer merch |

Practical tip: match personalization to the surface users touch. Powder-coated zones accept laser and high-quality print well and maintain a secure grip. Avoid placing the slickest finishes exactly where users hold the bottle; that space is best for textured coatings or silicone bands.

Manufacturing and Design: Grip Without the Headaches

If you intend to commission a proprietary, grip-forward plastic bottle instead of customizing an existing SKU, plan for the realities of blow-molding. Engineering sources recommend prototyping early with 3D-printed samples to validate feel and balance before cutting steel. Complex undercuts, sharp angles, or deep waistlines inflate mold costs and increase error rates. A typical pathway from concept to first production can span about 6–12 weeks, with roughly one to two weeks for design and prototyping, four to six weeks for mold manufacture, and one to two weeks for pilot production and QA (ibottler). Costs range from a few thousand dollars for simple, single-cavity prototype molds into the tens of thousands for complex or multi-cavity production tools. This is precisely why on-demand personalization of proven bottles is so attractive for many sellers—it captures the margin and branding upside with far less capital risk.

Labeling and branding also flow from shape. Ajanta Bottle’s guidance to plan flat or bounded label panels early helps ensure you can deliver crisp, legible graphics without compromising stability. Round shapes generally move faster on lines and avoid orientation jams; square faces can present beautifully but need greater diligence in mechanical handling.

Buying Guide for DTC, Merch, and Dropshipping Programs

Start with who will carry the bottle and how. For kids and students, a lightweight, easy-grip plastic with a flip-top or straw lid in a 12–18 oz range travels well in backpacks and won’t feel unwieldy at desks. For office and wellness programs, insulated stainless with a powder coat, a covered straw or chug lid, and 20–26 oz capacity hits the comfort and premium notes. For sports teams, opt for 28–32 oz bottles with strong carry loops or side handles and lids that allow quick, spill-resistant sips. For executive or VIP gifts, choose established brands and laser engraving to convey longevity and quality—4imprint references known names like Hydro Flask and CamelBak in their assortment, which can signal premium standards.

Operationally, there are reliable shortcuts. Order a sample or two with draft art to validate grip, finish, and imprint scale before committing to a batch; 4imprint’s free samples and art assistance exist for this exact step. Validate claims like “BPA-free” and “dishwasher safe” in the vendor’s spec sheet and confirm replacement lids or straws are available. VistaPrint and similar providers often run seasonal promotions and have low or flexible minimums, which makes A/B testing pairs of sizes and lids feasible. When you do bulk, use color swatches and proof approvals to confirm batch consistency; lead times and Pantone matching can drift without tight controls.

For dropshipping, prefer SKUs with reliable inbound supply and standardized personalization workflows like laser or UV on popular bottles. Confirm that the personalization area stays clear of primary grip zones to protect both the art and the user experience. If you need full-wrap art, leverage surfaces designed for it, such as coated white exteriors noted by Walmart Photo.

Care and Maintenance That Preserve Grip and Customization

Engraved marks are largely maintenance-free; printed marks last when you avoid abrasives. Hand-washing printed designs extends life, while most engraved or powder-coated steel bodies tolerate routine cleaning. Wide mouths simplify brushing and ice loading and reduce hidden residue. Straw systems require a narrow brush; several reviewers and testers, including CNN Underscored and The Strategist, emphasize regular straw cleaning to avoid buildup and flavor retention. When selling, include a concise care card in the package: how to clean lids, whether the body is dishwasher-safe, and what to avoid with printed art. For plastics, reassure shoppers with “BPA-free” and, where relevant, “phthalate-free” and “BPS-free” statements; retail examples like the POGO water bottle page at Staples list those compliance points explicitly, which reduces support tickets.

Pros and Cons of Easy Grip Personalized Bottles

Comfortable grip and personalization improve adoption and brand impressions, but not every configuration is perfect for every user. Insulated stainless delivers a premium feel and strong temperature retention, yet it is heavier and can strain small hands without a well-designed handle. Lightweight plastic is budget-friendly and naturally grippy when molded with contours, but insulation is limited unless you step up to double-wall builds, and scuffs appear sooner with rough use. Straw lids promote frequent sipping and one-handed convenience, but they demand more cleaning diligence; chug spouts and flip-tops simplify cleaning and often seal more robustly in rugged conditions. Printing offers bold, colorful identities and full-wrap options; engraving is virtually permanent but limits color expression. The right choice is the one that aligns with the intended user, daily environment, and brand goals you want the bottle to serve.

Case Notes from the Field

In client launches across school, fitness, and corporate channels, I’ve repeatedly observed that two things increase day-to-day carry: a handle that fits the full hand without pinching, and a mouthpiece that opens with a positive, secure action. Requests for replacement lids and returns drop when users can open and lock the mouthpiece with certainty, and when the bottle fits the car cup holder. This aligns with Wirecutter’s note on locks and tapered bases and with CNN Underscored’s emphasis on lid durability and leak control. While I haven’t run academic studies, the pattern is consistent enough across programs to make me confident in recommending a strong handle, a positive-lock lid, and a base diameter that works in common cup holders as table-stakes ergonomics. My confidence is high for general audiences and moderate for specialized use like ultralight hiking, where weight can outweigh any other factor.

Compliance and Safety Notes

Shoppers look for clear material safety signals. “BPA-free” remains essential for plastics; brand leaders like Nalgene center that message. Retailer pages sometimes specify additional thresholds—lead-free, phthalate-free, BPS-free, and PVC-free—which are reassuring for institutional buyers. When offering personalization, avoid solvents or harsh cleaners in your care guidance; recommend soft sponges and mild soap, especially for printed art. For kids’ bottles, leakproof lids, rugged carry loops, and dishwasher-safe caps reduce day-to-day friction and make the bottle—and your brand—feel dependable.

Quick Selector: Match Comfort and Customization to the Job

Goal | Format to Favor | Personalization to Use |

|---|---|---|

Lightweight comfort for kids/students | BPA-free plastic, 12–18 oz, flip-top or straw | UV/digital print with bold names |

Premium daily carry | Insulated stainless, 20–26 oz, covered straw or chug | Laser engraving on powder coat |

Team practice and events | 28–32 oz with loop/handle, spout or push-pull | Screen/UV print; bold, readable |

Executive/employee gifts | Named brand stainless, 20–30 oz, chug or covered straw | Laser engraving, subtle art |

Creator or campus merch | Sublimation-ready white steel, wrap design | Full 360° wrap, high-contrast art |

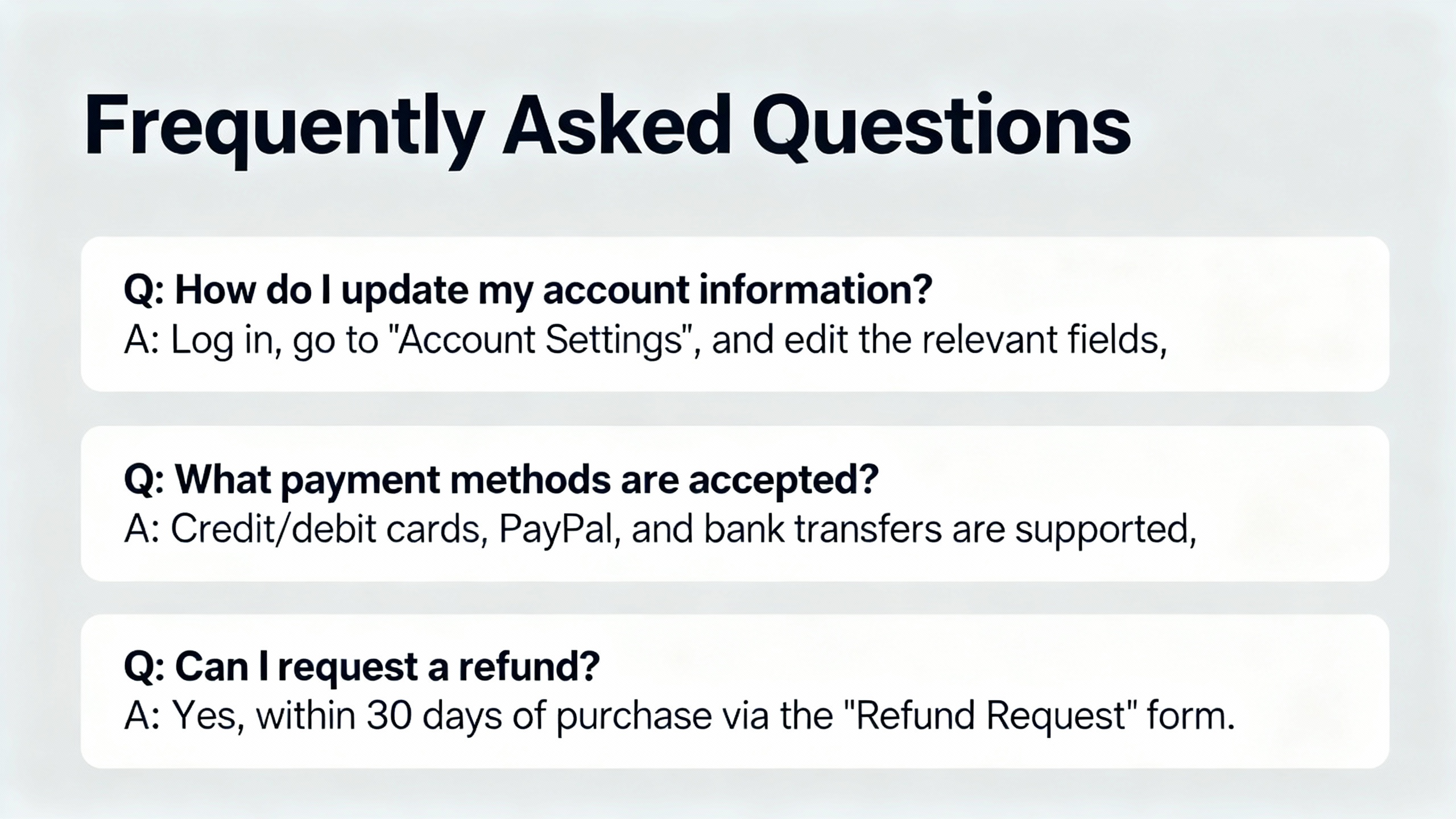

Frequently Asked Questions

What makes a bottle truly “easy grip” in real-world use?

True grip combines a shape that naturally fits the hand, a surface finish that resists slipping, and a mass balance that keeps the bottle steady when tilted. Design sources emphasize waist indentations or hourglass contours, textured powder coats or sleeves, and handles sized for a full hand. These factors help maintain control during walking, driving sips, and workouts.

Is laser engraving better than printing for durability?

Laser engraving on stainless steel is typically more durable because it removes or alters the coating to reveal steel, so there is nothing to peel. High-quality UV prints are also resilient and allow full color and wraps. Choose engraving for long-lived gifts and daily carry steel; choose UV or screen printing when color, photos, or larger logos are essential.

Which size should I choose for comfort and hydration?

For most adults, 16–24 oz balances weight, grip, and refill frequency. Teams and long sessions often prefer 28–32 oz to reduce refills. Kids tend to do better with 12–18 oz. As a general reference, Harvard Medical School notes about 2–3 cups per hour in typical conditions, which equals roughly 16–24 oz; calibrate by activity level and personal guidance.

Are straw lids harder to keep clean?

Straw systems require a bit more care. Use a narrow brush for the straw and clean seals periodically. Covered straws or lids with locks help with hygiene and leak control. If you want simpler upkeep, a chug spout or flip-top with a wide opening is easier to scrub.

What if I want a proprietary ergonomic shape for my brand?

If you commission a custom plastic shape, prototype early to validate grip and balance, and be mindful that complex contours raise tooling costs. A concept-to-first-shot timeline of about 6–12 weeks is common in blow-molding, with costs that can range from a few thousand dollars to the tens of thousands depending on complexity. Many brands start with on-demand personalization of proven bottles to validate demand before cutting molds.

How do I avoid slippery finishes that undermine grip?

Position smooth or glossy art finishes away from primary grip zones and favor powder coats or silicone bands where hands make contact. Providers like Walmart Photo and 4imprint offer formats that let you place art on central panels or wraps while keeping textured zones for handling.

Key Takeaway

Comfortable custom handling is a design system, not a sticker. Start with an ergonomic body and a confident lid you can operate one-handed. Choose materials and sizes that match the user’s day, then apply personalization that lasts in the exact places that users don’t need to grip. Use samples and proofed art to confirm feel and legibility before scaling. Do those things well and the bottle becomes a habit—and your brand becomes part of that habit.

References

This article draws on reporting and testing from The Strategist, CNN Underscored, GearLab, and Wirecutter; design and manufacturing guidance from ibottler and Ajanta Bottle; retail and personalization specifications from Walmart Photo, VistaPrint, and 4imprint; promotional and branding guidance from Swagify and ProWorks; safety and catalog cues from Nalgene, Staples, and Quality Logo Products; and group-buy practicalities summarized by Totally Promotional with hydration context from Harvard Medical School.

- https://www.bottlepro.net/hydration-blog/what-is-the-best-water-bottle-our-biggest-comparison-yet

- https://nalgene.com/?srsltid=AfmBOopL8wQH7AZ4atTy21Y4usWIEyYj8yZBVFEUZksQNB5lMukeus_V

- https://www.youngsomething.com/a-5-design-features-to-consider-when-customizing-a-water-bottle.html

- https://atlantasparks.com/best-personalized-water-bottles/

- https://www.fayren.com/news/what-to-consider-when-designing-a-water-bottle

- https://ibottler.com/custom-sports-drink-bottle-design-from-capacity-to-grip-how-does-it-impact-sales/

- https://www.qualitylogoproducts.com/custom-waterbottles/gripbottle-flexible-straw-32oz.htm

- https://www.staples.com/buy/quick-grip-water-bottles-0aiz00a

- https://blog.totallypromotional.com/how-to-select-the-right-water-bottle/

- https://photos3.walmart.com/category/1263-custom-water-bottles?srsltid=AfmBOoo0ZpcnVsTaOICc8SIIiLeMny9bfQ7TKSEGeJIp8yWBLHUvYpvx