Modern Personalized Products: Contemporary Custom Designs

Personalized products moved from novelty to expectation, and the shift is reshaping how ambitious founders build on-demand printing and dropshipping businesses. In coaching hundreds of entrepreneurs, I’ve seen the same pattern repeat: when shoppers can co-create the product and preview the outcome—in real time—they decide faster, pay more willingly, and come back more often. That’s not just anecdote. Research from 3D Cloud reports that most shoppers decide faster with real-time configuration and feel more confident using 3D or AR visualizations, while a large share prefer and stay loyal to brands that offer digital customization. Meanwhile, Graphics Pro highlights a personalized gifts market estimated at $41 billion in 2023 with projections that point to substantially higher demand by 2032, reinforcing that personalization is a durable growth avenue rather than a trend to chase.

This article translates those signals into a founder’s playbook. I’ll demystify contemporary customization, show what technology and operations you actually need, explain pricing and policy choices that preserve margin, and outline a practical rollout path that avoids common pitfalls. The goal is profitable personalization at scale, not one-off craft projects that only work on weekends.

What “Personalized” Really Means Now

There are two related concepts to get straight on day one. Customization lets the shopper explicitly choose attributes—color, material, monogram, components, and features. Personalization adapts the experience automatically based on data, so the right product, message, or promotion appears at the right time with minimal effort from the shopper. The distinction matters because combining both drives the biggest lift. Lumenalta explains that data-led personalization, when paired with user-controlled customization, yields more relevant, higher-converting experiences. WP Configurator echoes this split, noting that customization is user-driven in the product builder, while personalization is system-driven across the journey.

A third term—mass customization—sits at the heart of contemporary custom design. Katana and Bain & Company describe it as delivering individualized configurations at near mass-production efficiency. The strategy isn’t to handcraft every order; it’s to let customers configure within smart guardrails and fulfill with standardized processes, materials, and digital workflows. Bain’s perspective further ties customization to loyalty and premiums, with consumers often willing to wait longer for custom items, and many ready to pay more for products made to their preferences.

Why Consumers Buy Custom Today

Shoppers are not just browsing; they’re co-creating. Adobe points to a clear behavioral shift: relevance cuts through ad overload, personalized emails convert far better than generic blasts, and a large majority of customers prefer brands that personalize communications. McKinsey adds that most consumers expect personalized interactions and feel frustrated when they don’t get them. The growth impact is tangible. Adobe and McKinsey both link personalization to revenue gains, with meaningful boosts to repeat purchase and marketing efficiency when brands tailor experiences across channels.

Willingness to pay is equally important. Deloitte’s findings, cited by The Good, show that one in five shoppers is willing to pay a 20% premium for personalized products. Print on-demand leaders like Shopify observe that personalization increases average order value and reduces inventory risk because you only make what’s sold. That combination—higher price tolerance with lower inventory burden—is why mass customization has become a core differentiator rather than a niche experiment.

The Five Lenses of Customization You Can Put to Work

Functional customization changes how a product behaves or fits. 3D Cloud cites examples like office chairs tuned to posture and helmets adjusted for precise protection and comfort. When shoppers can see and feel the benefit—ideally via 3D or AR—conversion rises because you’re improving performance, not just aesthetics.

Component customization lets shoppers mix and match parts from a curated set, such as bicycle stems and saddles for body fit or guitar necks and hardware to shape sound and feel. Done well, component choices map to clear benefits, and the system blocks invalid combinations, so the experience is empowering, not confusing.

Aesthetic customization is the gateway for most new brands. Colorways, panels, and finishes connect quickly to taste and environment. As The Good emphasizes, precise live previews are essential, as they reduce uncertainty and the likelihood of returns by aligning what the shopper sees with what arrives.

Personalized elements add names, monograms, logos, or uploaded imagery. Platforms like Zazzle and Shutterfly popularized this, and print-on-demand networks such as Printify extend it to independent creators who need turnkey production and fulfillment. The key is clean artwork handling, clear terms for approvals, and transparent lead times.

Mass customization weaves all of the above into scalable operations. 3D Cloud suggests combining modular options with a configurator that updates visuals, specs, and pricing in real time. Katana recommends an ERP backbone that manages unlimited variants, live material allocation, and production scheduling, preventing the “Excel spaghetti” that sinks many growing shops.

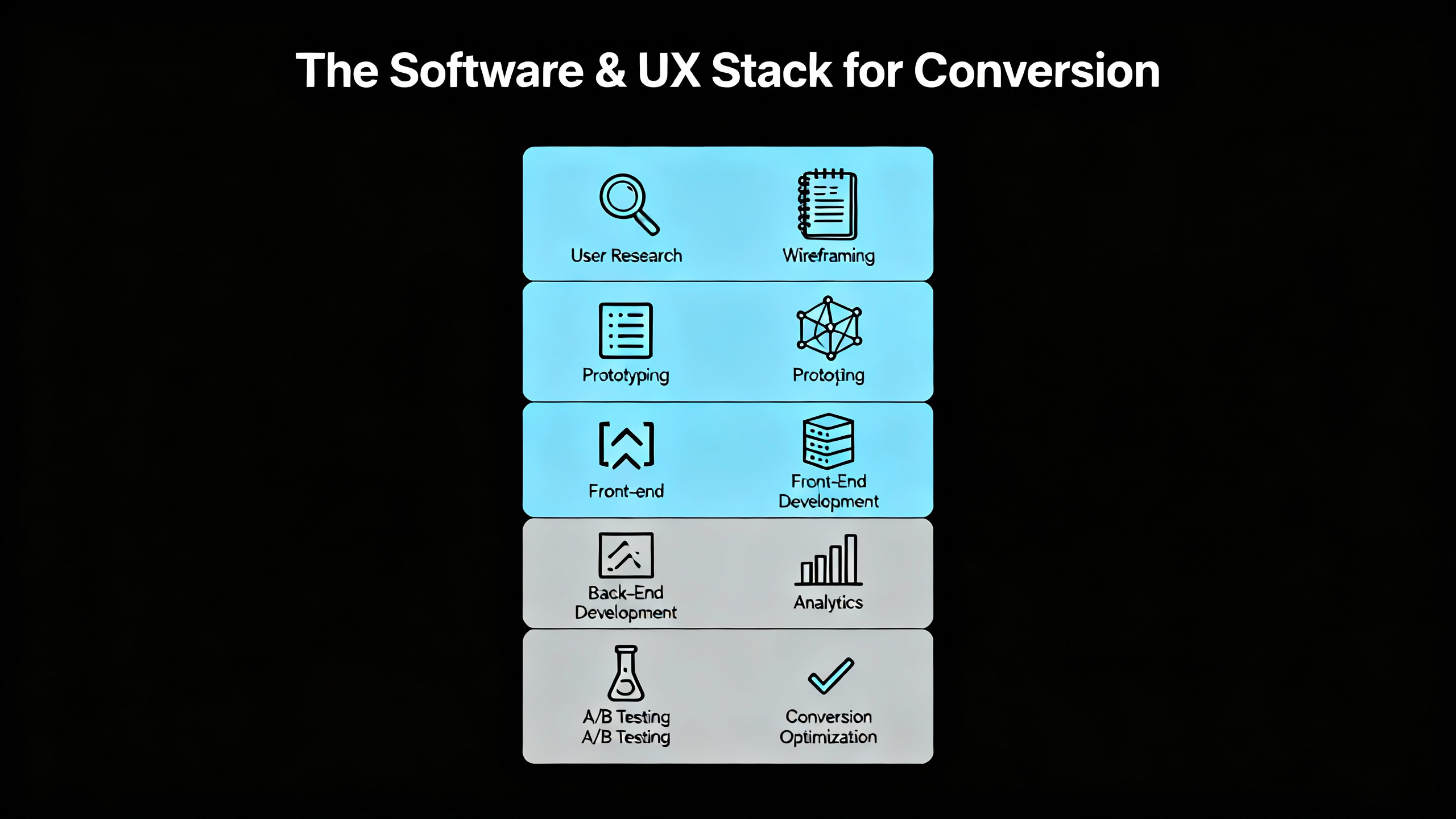

The Software and UX Stack That Makes It Convert

Conversion hinges on clarity and control. 3D Cloud recommends 3D and AR configurators that update visuals, specifications, and price instantly as options change. The Good advises progressive disclosure, breaking decisions into steps with helpful defaults and save-and-share options so customers can pause and return without losing work. Smart Customizer adds a practical emphasis on speed, mobile responsiveness, live previews, and reliable error handling. WP Configurator and The Good both underline the importance of guardrails: constraint logic prevents invalid combinations and simplifies choice architecture.

Under the surface, the system should connect to product information and manufacturing data, as WP Configurator notes, and integrate with your e-commerce platform for checkout and order capture. Adobe and Lumenalta advocate using a CRM or CDP as a real-time data hub so marketing personalization stays in sync with product customization. Bazaarvoice points to the role of user-generated content and reviews, which can be algorithmically woven into email and on-site experiences to provide social proof where it matters most. ThreeKit, cited in Gray’s industry coverage, provides an example of specialist partners that offer 3D interactive builders when in-house capabilities are not feasible right away.

Production Models and Tools You Actually Need

Sublimation remains a favorite in on-demand printing because it yields photorealistic results on polyester garments and polymer-coated substrates. The limitation is material compatibility, but for drinkware, apparel with the right blends, and flat goods like coasters, it produces crisp, lasting images. DTF and DTG have surged because they place vibrant graphics on a wide range of fabrics; they involve pretreatment and additional steps when done in-house, but they deliver versatile output and can be hybridized by sourcing pre-made DTF transfers and handling pressing and fulfillment in your workshop.

Laser engraving turns standard goods into heirloom-grade pieces. Graphics Pro emphasizes its reliability across wood, leather, glass, coated metals, and some plastics, and notes that engraver quality, uptime, and vendor support matter to production consistency. The appeal is permanence. Maker communities often call out that engraved designs don’t scratch or fade the way many surface prints do. Epoxy, by contrast, is a creative medium for coating and casting; it opens unique design languages for tumblers, pens, and decor when combined with pigments and substrates, but it also introduces material handling and curing considerations that grow with volume.

The matrix below aligns methods with the benefits and trade-offs founders most often wrestle with. Use it to decide on your primary method and where to add breadth later.

Method | Best For | Strengths | Trade-offs | Care Notes |

|---|---|---|---|---|

Sublimation | Apparel with polyester content, coated drinkware, flat goods | Photorealistic results and smooth finishes | Limited to compatible materials and coatings | Confirm vendor guidelines for pressing times and cleaning; verify dishwasher recommendations with suppliers |

DTF / DTG | Apparel and soft goods with varied fabrics | Vibrant prints with flexible application options | Requires pretreatment and more steps if printing in-house | Follow supplier wash guidance; test samples before launch |

Laser Engraving | Wood, leather, glass, coated metals, some plastics | Permanent marks with a premium, tactile look | Equipment selection and uptime directly affect consistency | Wipe with non-abrasive cleaners appropriate to the material |

Epoxy Coating/Casting | Tumblers, pens, decor, molded pieces | Distinctive, high-perceived-value finishes | Curing time and handling add operational complexity | Share handling guidance with customers; avoid high heat exposure if vendor advises |

Pricing, Margins, and What the Data Actually Supports

Price to value, not just to cost. Deloitte’s evidence, cited by The Good and ThreeKit, shows that many consumers will pay approximately 20% more for personalized items, and Adobe notes that personalized experiences can lift revenue meaningfully. Shopify observes that customization often increases average order value and helps you avoid dead stock since you produce only what has sold. These are structural advantages that justify value-based pricing—especially when your configurator demonstrates the difference the shopper is paying for.

Community data can help triangulate starting points, with a caveat. Maker communities report retail ranges for drinkware and decor that vary by material, finish, and detail, including premium pricing for rhinestone and specialty finishes. Treat these as directional rather than prescriptive. Your price must reflect your brand positioning, your lead times, and your cost-to-serve. The Good advises surfacing price deltas in the configurator and flagging longer lead times up front. That transparency reduces cart friction and avoids uncomfortable post-purchase conversations.

A reliable approach is to publish an anchor price for the base configuration, then show deltas as customers add features or premium materials. Keep the math simple inside your operations by standardizing option tiers and mapping each tier to a known cost and time impact. Move away from bespoke quoting unless you are intentionally positioning as a custom atelier with fewer, higher-ticket orders.

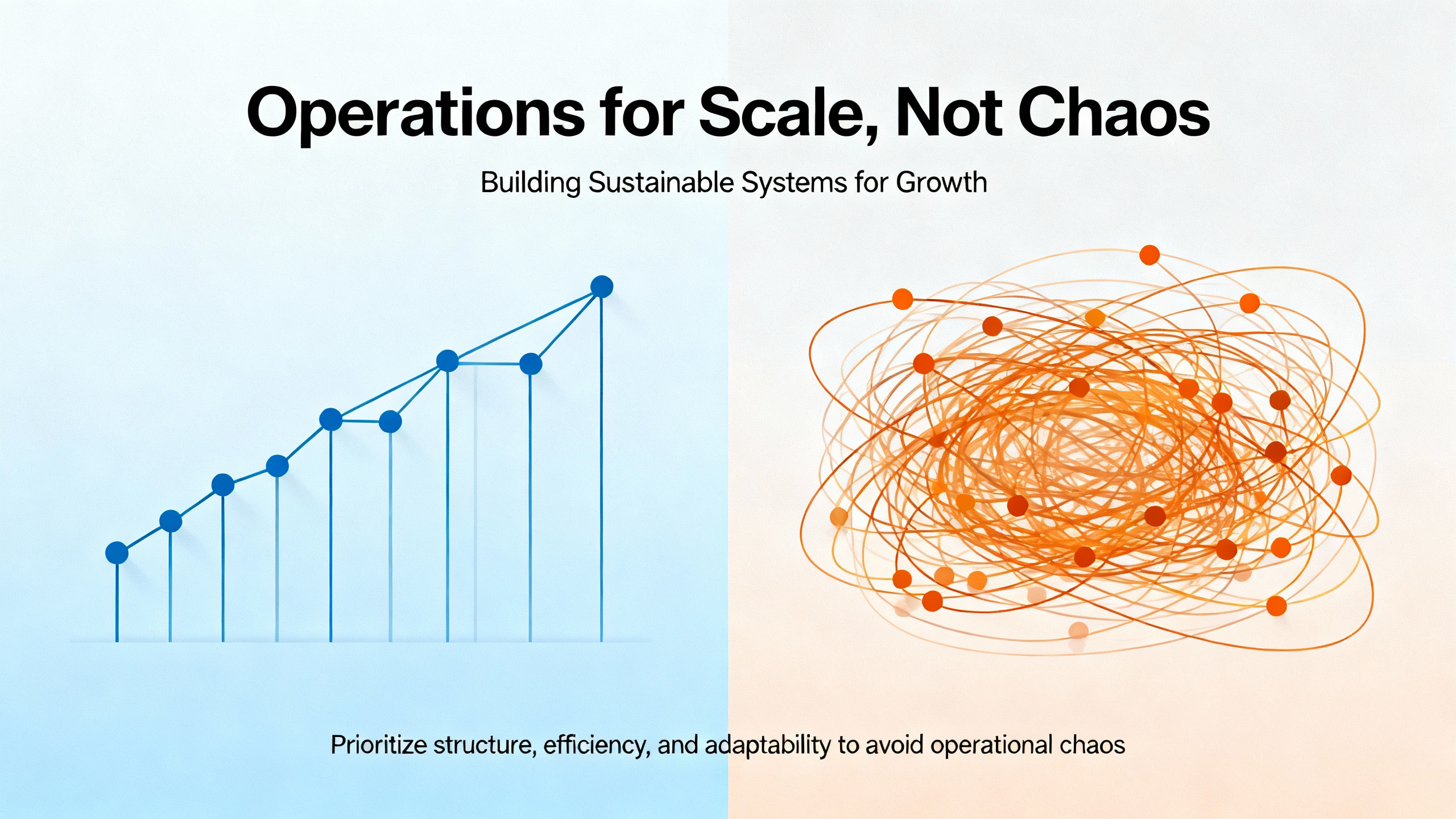

Operations for Scale, Not Chaos

Mass customization fails when variant sprawl outruns your systems. Katana warns that spreadsheets collapse under the weight of options; production software that supports unlimited SKUs and automatic material allocation will prevent shortages and missed promises. Graphics Pro’s guidance on jigs and fixtures is equally practical: create fixtures for irregular items so placement is repeatable, setup time is short, and error rates are low. Reliability and vendor support for engravers and printers will decide whether your peak season is profitable; uptime is a margin lever.

WP Configurator recommends standardizing bill-of-material templates and defining constraint logic so the front-end can only emit valid orders. Add artwork proofs and approvals for personalized graphics and lock down policies on cancellations and changes once a job hits production. The same source stresses performance and accessibility in your configurator. The Good adds a critical customer experience point: let shoppers save and share designs so they can co-decide with partners, and pace decisions to reduce choice overload. From the supply side, Katana’s integrated purchasing plans and floor-level control help teams hit promised ship dates without memorizing every step.

Marketing Personalization That Sells Custom Work

Adobe summarizes why personalization in marketing matters: relevance cuts through noise, most consumers prefer tailored messaging, and generic blasts annoy. McKinsey ties personalization to performance, with material sales and margin lift from targeted promotions and far faster content production when teams use modern AI workflows under good governance. Bazaarvoice demonstrates how reviews and user-generated content can power segment-aware messages, while Smart Customizer and The Good point toward conversion-oriented on-site UX for both standard and customizable products.

The practical stack looks like this. Use a CRM or CDP as the single source of truth for profiles and events from site, configurator, and support, then orchestrate messages across email, SMS, and on-site placements based on lifecycle stage. Start small with a handful of high-impact moments: landing pages that greet by context, browse and cart abandonment for unfinished designs, loyalty nudges tied to birthdays or anniversaries, and post-purchase messages that invite reviews with photos of the final personalized item. ThreeKit highlights the power of explainers and demo videos; adding video to an announcement can raise conversion in email, and the same clip can live on your product pages to reduce hesitation.

Respect for privacy is not optional. Lumenalta and Adobe advise clarity on data use, opt-ins, and preference centers. Give shoppers control, explain the value exchange in plain language, and provide easy opt-outs. Thoughtful personalization strengthens trust; intrusive retargeting and data inaccuracies do the opposite.

Category Playbook and Real-World Inspiration

3D Cloud’s sector examples are helpful when choosing a niche. Apparel and footwear benefit from colorways, panels, and monograms that are both expressive and fast to configure. Furniture and home decor thrive on finishes and sizes mapped to real spaces, especially when paired with room planners and photo-real renderings. Daily-use goods like drinkware and phone cases sell when the upload flow is frictionless and the preview looks like the end product.

The Good and Gray point to brands that pioneered or perfected parts of the journey. Footwear and apparel programs that guide decisions step by step, furniture brands that use 3D and progressive disclosure to manage complexity, and automotive and health examples that use scans and 3D printing to hit a precise fit all illustrate the same principle: let the customer be the designer, but do the hard operational work so they can’t make a bad choice. The reward is loyalty that outlasts seasonal promotions.

Care and Buying Tips for Shoppers and Merchants

Graphics Pro suggests choosing materials that suit the method. Wood, leather, glass, coated metals, and some plastics are engraver-friendly and retain a crisp mark. If you sell sublimated apparel, your product detail pages should explain that polyester content is required for the best results and that prints are embedded in the fibers rather than sitting on top. For DTF and DTG, guide buyers with simple care suggestions drawn from your supplier’s documentation and encourage them to test new pieces with gentle washing first. If you sell epoxy-coated items, share handling guidance from your maker notes so customers can enjoy the finish as intended.

For merchants, the lowest-cost returns are the ones you prevent. The Good recommends real-life previews and clear disclosures about lead times and option-dependent pricing. WP Configurator advises setting policies for customized items, including proofs, limited cancellation windows, and terms on non-returnable products when personalization is executed. Your customers will reward clarity; buyers of personalized goods value the story of the item as much as the object itself.

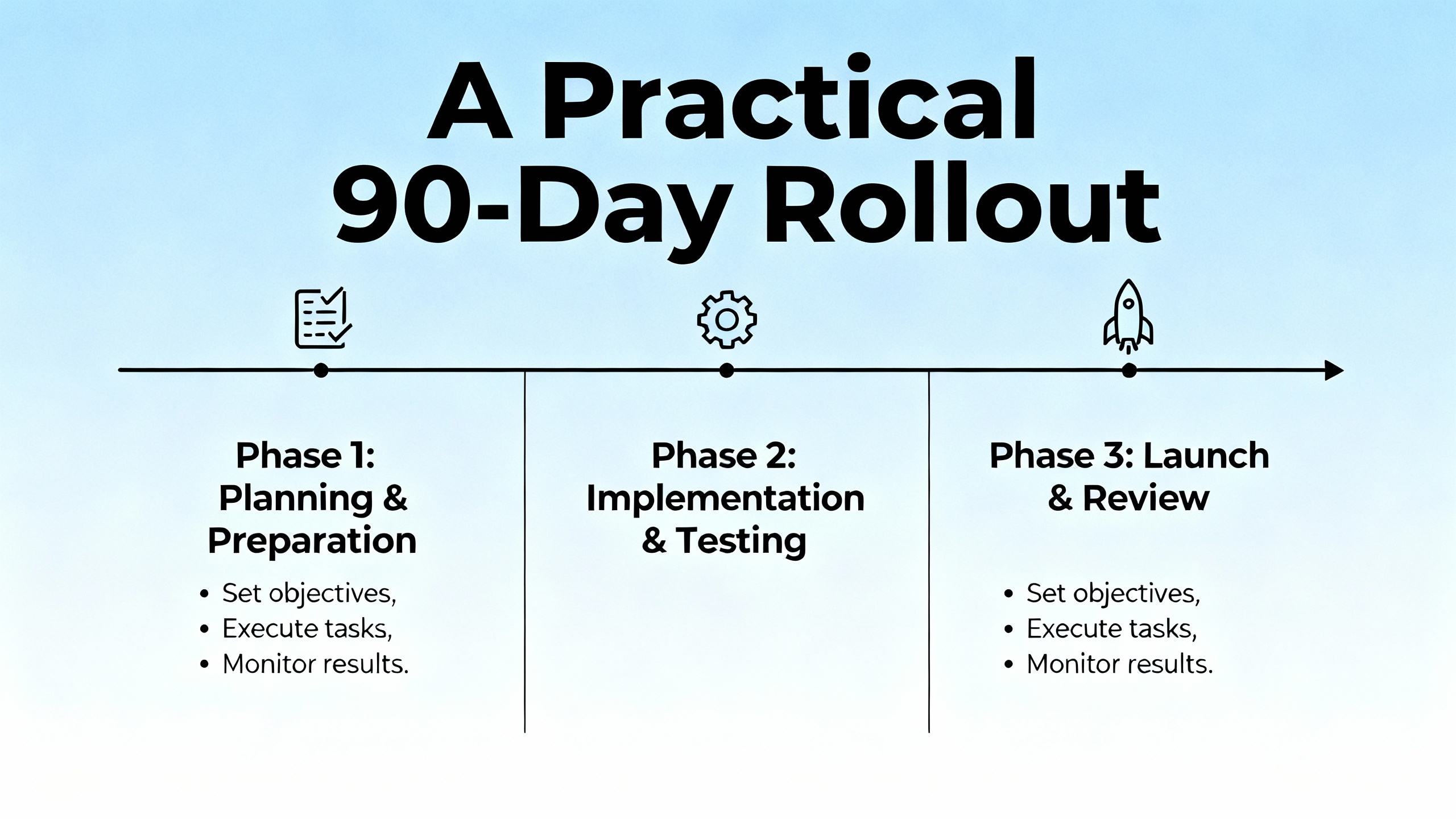

A Practical 90-Day Rollout

Start with discovery and design in your first month. Interview customers, review past orders and support tickets, and shortlist two to three hero SKUs whose customization attributes are obvious to shoppers and simple for your team to produce. Adopt a configurator with real-time previews and price updates, integrate it with your platform and CRM, and define constraint logic so your first workflows are bulletproof. In the second month, soft launch with limited options, publish an explainer video, and run targeted messages to your existing list. Use save-and-share and cart-abandon events to power your follow-ups, and watch where shoppers hesitate or drop. In the third month, scale thoughtfully. Add one more attribute where data shows demand, invest in fixtures or process improvements that cut setup time, and expand personalization in marketing via segmented email and on-site placements. Schedule a weekly review across operations, marketing, and support so your team can fix friction points before they turn into churn.

The Future: 3D, Data, and Delight at Scale

3D and AR configurators are no longer experimental; 3D Cloud’s shopper insights tie them directly to faster decisions, higher confidence, and loyalty. ERP-grade planning for variants has moved within reach for small teams through tools like Katana that centralize live inventory, purchasing, and floor-level control. Marketing personalization continues its march, with Adobe and McKinsey showing that teams who unify data and orchestrate cross-channel activation earn real revenue lift. The shape of the opportunity is clear: the next generation of on-demand businesses will be those that make co-creation enjoyable on the surface and make mass customization routine behind the scenes.

FAQ

What margins can a small brand expect with personalization? Benchmarks vary by method and market, but several sources point to meaningful uplifts when customization is combined with a quality experience. Deloitte’s research, cited by The Good and ThreeKit, notes that many consumers will pay a premium for personalized items, and Adobe and McKinsey connect personalized experiences to overall revenue gains. Price to value, anchor your base configuration clearly, and show option deltas transparently in the configurator.

Do I need 3D or AR to succeed? Not always, but the data is compelling. 3D Cloud’s research ties real-time configuration to faster decisions, higher confidence, and stronger loyalty. If budget is tight, start with crisp two-dimensional live previews and clear step sequencing, then graduate to 3D or AR for higher-consideration items where space fit and finish are decisive.

How should I handle returns and cancellations for custom items? WP Configurator recommends setting explicit policies for proofs, approval checkpoints, lead times, and limited cancellation windows once production begins. The Good adds that transparency around lead time and price changes up front prevents surprises. Many brands limit returns for personalized items, and clear pre-purchase previews reduce the need for exceptions.

In a market where sameness races to the bottom, customization is the entrepreneur’s quality moat. If you combine a confident design experience with reliable production and thoughtful personalization in your marketing, you won’t just sell more; you’ll earn the kind of loyalty that compounds with every order.

References

- https://www.smartcustomizer.com/blog

- https://3dcloud.com/product-customization-examples/

- https://lumenalta.com/insights/what-is-personalization

- https://www.shopify.com/blog/product-customization

- https://thestartupweekly.com/how-to-increase-sales-with-product-personalization/

- https://www.threekit.com/blog/8-ways-communicate-new-product-customization-options-customers

- https://userguiding.com/blog/personalized-product-experience

- https://www.wtpbiz.com/blog/how-to-grow-business-of-personalized-products

- https://business.adobe.com/blog/basics/marketing-personalization

- https://www.bain.com/insights/making-it-personal-rules-for-success-in-product-customization/